Menu

Close

Menu

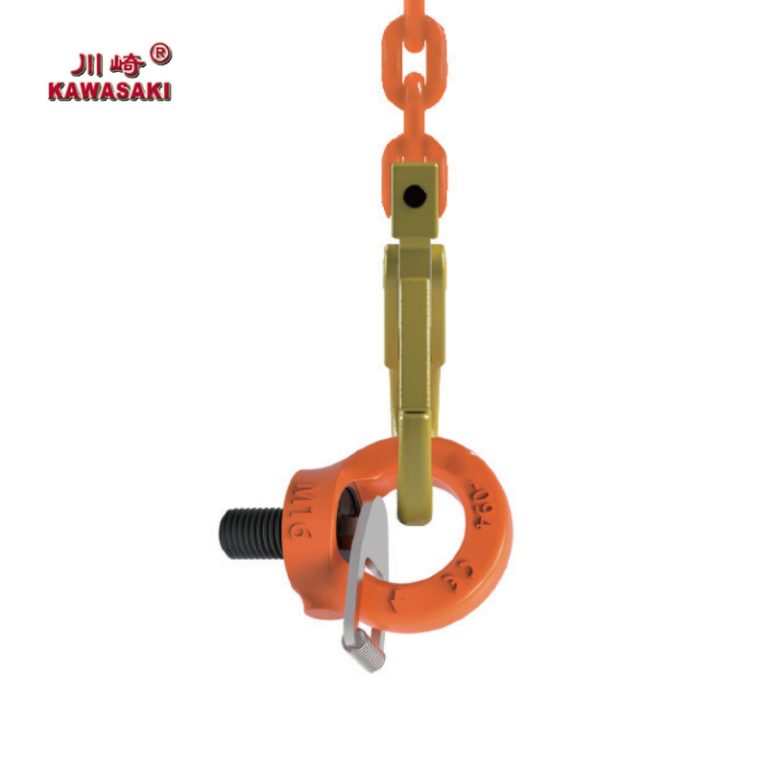

The lifting ring body can rotate in the direction of force to adjust the angle of force.

The link ring can automatically adjust the force angle with the stretching direction.Working tensile is the same in any direction, safety factor is 4:1.

Different kinds of thread are available,wide range of WLL load(M8-M48,0.3T-12T);the available thread including:Metric thread, Metric fine thread,UNc thread,UNF thread, Bsw thread and so on.

Lifting points are made of alloy steel precision forging, with a tensile strength greater than 1080Mpa after quenching and tempering. The

surface of the lifting ring is electrostatic coating to improve its anti-corrosion ability.

After passing the inspection with a 6g go/no go gauge, it is suitable for precision threaded holes.

| ITEM NO. | WLL/T | Thread M | Dimensions /mm | Nm | Weight Kg | |||||||

| E | A | B | C | D | F | w | C | |||||

| 094-M8 | 0.3 | M8 × 1.25 | 12 | 40 | 25 | 8 | 9.5 | 26 | 44 | 6 | 10-40 | 0.15 |

| 094-M10 | 0.4 | M10×1.5 | 15 | 40 | 25 | 8 | 9.5 | 26 | 44 | 6 | 10-40 | 0.15 |

| 094-M12 | 0.75 | M12×1.75 | 18 | 47 | 30 | 10 | 11 | 32 | 52 | 8 | 15·40 | 0.2 |

| 094-M14 | 0.75 | M14×2.0 | 18 | 47 | 30 | 10 | 11 | 32 | 52 | 8 | 30-100 | 0.2 |

| 094-M16 | 1.5 | M16×2.0 | 24 | 54 | 35 | 14 | 13 | 39 | 61 | 10 | 45-130 | 0.35 |

| 094-M18 | 1.5 | M18×2.5 | 24 | 54 | 35 | 14 | 13 | 39 | 61 | 10 | 100-170 | 0.35 |

| 094-M20 | 2.3 | M20 × 2.5 | 30 | 63 | 40 | 16 | 15 | 47 | 70 | 12 | 100-170 | 0.6 |

| 094-M22 | 2.3 | M22 × 2.5 | 30 | 63 | 40 | 16 | 15 | 47 | 70 | 12 | 100-170 | 0.6 |

| 094-M24 | 3.2 | M24 × 3.0 | 36 | 73 | 48 | 19 | 18 | 55 | 84 | 14 | 190-280 | 1 |

| 094-M27 | 3.2 | M27 × 3.0 | 36 | 73 | 48 | 19 | 18 | 55 | 84 | 14 | 250-500 | 1 |

| 094-M30 | 4.5 | M30 × 3.5 | 45 | 91.5 | 60 | 24 | 22.5 | 67 | 105 | 17 | 270-600 | 2 |

| 094-M33 | 4.5 | M33× 3.5 | 45 | 91.5 | 60 | 24 | 22.5 | 67 | 105 | 17 | 270-600 | 2 |

| 094-M36 | 7 | M36 × 4.0 | 54 | 114 | 72 | 29 | 27 | 85 | 126 | 22 | 270-600 | 3 |

| 094-M42 | 9 | M42 ×4.5 | 63 | 130 | 82 | 34 | 32.5 | 98 | 147 | 22 | 350-800 | 5 |

| 094 -M48 | 12 | M48× 5.0 | 72 | 151 | 96 | 38 | 36 | 114 | 168 | 27 | 350-800 | 7.5 |

| Number of pieces | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 Asymmetry | |||

| Inclination angle | 0° | 0° | 90° | 90° | 0-45° | 45-60° | Asymmetry | 0-45° | 45-60° | Asymmetry | |

| ITEM NO. | Thread M | WLL/T | |||||||||

| 094-M8 | 8 | 1 | 2 | 0.3 | 0.6 | 0.42 | 0.3 | 0.3 | 0.63 | 0.45 | 0.3 |

| 094-M10 | 10 | 1 | 2 | 0.4 | 0.8 | 0.56 | 0.4 | 0.4 | 0.8 | 0.6 | 0.4 |

| 094-M12 | 12 | 2 | 4 | 0.75 | 1.5 | 1 | 0.75 | 0.75 | 1.5 | 1.1 | 0.75 |

| 094-M14 | 14 | 2 | 4 | 0.75 | 1.5 | 1 | 0.75 | 0.75 | 1.5 | 1.1 | 0.75 |

| 094-M16 | 16 | 4 | 8 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 |

| 094-M18 | 18 | 4 | 8 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 |

| 094-M20 | 20 | 6 | 12 | 2.3 | 4.6 | 3.2 | 2.3 | 2.3 | 4.8 | 3.4 | 2.3 |

| 094-M22 | 22 | 6 | 12 | 2.3 | 4.6 | 3.2 | 2.3 | 2.3 | 4.8 | 3.4 | 2.3 |

| 094-M24 | 24 | 8 | 16 | 3.2 | 6.4 | 4.5 | 3.2 | 3.2 | 6.7 | 4.8 | 3.2 |

| 094-M27 | 27 | 8 | 16 | 3.2 | 6.4 | 4.5 | 3.2 | 3.2 | 6.7 | 4.8 | 3.2 |

| 094-M30 | 30 | 12 | 24 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.4 | 6.7 | 4.5 |

| 094-M33 | 33 | 12 | 24 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.4 | 6.7 | 4.5 |

| 094-M36 | 36 | 16 | 32 | 7 | 14 | 9.8 | 7 | 7 | 14.7 | 10.5 | 7 |

| 094-M42 | 42 | 24 | 48 | 9 | 18 | 12.6 | 9 | 9 | 18.9 | 13.5 | 9 |

| 094-M48 | 48 | 32 | 64 | 12 | 24 | 16.8 | 12 | 12 | 25 | 18 | 12 |

| Number of pieces Inclination angle | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 Asymmetry | |||

| 0° | 0° | 90° | 90° | 0-45° | 45 -60° | Asymmetry | 0-45° | 45 -60° | |||

| ITEM NO. | Thread M | WLL /T | |||||||||

| 094-3/8 | 3/8 | 1 | 2 | 0.4 | 0.8 | 0.56 | 0.4 | 0.4 | 0.8 | 0.6 | 0.4 |

| 094-1/2 | 1/2 | 2 | 4 | 0.75 | 1.5 | 1 | 0.75 | 0.75 | 1.5 | 1.1 | 0.75 |

| 394-5/8 | 5/8 | 4 | 8 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 |

| 394 -3/4 | 3/4 | 6 | 12 | 2.3 | 4.6 | 3.2 | 2.3 | 2.3 | 4.8 | 3.4 | 2.3 |

| 094-7/8 | 7/8 | 6 | 12 | 2.3 | 4.6 | 3.2 | 2.3 | 2.3 | 4.8 | 3.4 | 2.3 |

| 094-1 | 1 | 8 | 16 | 3.2 | 6.4 | 4.5 | 3.2 | 3.2 | 6.7 | 4.8 | 3.2 |

| 094-1-1/4 | 1-1/4 | 12 | 24 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.4 | 6.7 | 4.5 |

| 094-1-1/2 | 1-1/2 | 16 | 32 | 7 | 14 | 9.8 | 7 | 7 | 14.7 | 10.5 | 7 |

| 094-1-3/4 | 1-3/4 | 24 | 48 | 9 | 18 | 12.6 | 9 | 9 | 18.9 | 13.5 | 9 |

| 094-2 | 2 | 32 | 64 | 12 | 24 | 16.8 | 12 | 12 | 25 | 18 | 12 |

| ITEM NO. | WLL/T | Thread | Dimensions / mm | Nm | Weight Kg | ||||||||

| M | TPI | E | A | B | C | D | F | W | S | ||||

| 094-3/8 | 0.4 | 3/8 | 16 | 15 | 40 | 25 | 8 | 9.5 | 26 | 44 | 6 | 10-40 | 0.15 |

| 094-1/2 | 0.75 | 1/2 | 13 | 18 | 47 | 30 | 10 | 11 | 32 | 52 | 8 | 15-40 | 0.2 |

| 094-5/8 | 1.5 | 5/8 | 11 | 24 | 54 | 35 | 14 | 13 | 39 | 61 | 10 | 45·130 | 0.35 |

| 094 -3/4 | 2.3 | 3/4 | 10 | 30 | 63 | 40 | 16 | 15 | 47 | 70 | 12 | 45-130 | 0.6 |

| 094-7/8 | 2.3 | 7/8 | 9 | 30 | 63 | 40 | 16 | 15 | 47 | 70 | 12 | 100-170 | 0.6 |

| 094-1 | 3.2 | 1 | 8 | 36 | 73 | 48 | 19 | 18 | 55 | 84 | 14 | 190-280 | 1 |

| 094-1-1/4 | 4.5 | 1-1/4 | 7 | 45 | 91.5 | 60 | 24 | 22.5 | 67 | 105 | 17 | 270-600 | 2 |

| 094-1-1/2 | 7 | 1-1/2 | 6 | 54 | 114 | 72 | 29 | 27 | 85 | 126 | 22 | 270-600 | 3 |

| 094-1-3/4 | 9 | 1-3/4 | 5 | 63 | 130 | 82 | 34 | 32.5 | 98 | 147 | 22 | 350-800 | 5 |

| 094-2 | 12 | 2 | 4.5 | 72 | 151 | 96 | 38 | 36 | 114 | 168 | 27 | 350-800 | 7.5 |