Lifting the Load Safely

Once the load is securely attached and the hand chain is positioned, it’s time to lift the load safely. This process requires careful attention to detail and adherence to safety practices to avoid accidents or equipment damage. Begin by standing in a stable position and ensuring that your footing is secure. Slowly and steadily pull the hand chain to begin lifting the load. Make sure to apply even and consistent force to avoid sudden movements that could destabilize the load. Monitor the lifting process closely and stop if you notice any issues such as unusual noises or resistance. This step-by-step approach to lifting ensures that the load is raised in a controlled and safe manner.

Lowering the Load Properly

Once you have completed your task and need to lower the load, it is imperative to do so with the same level of care and precision. To begin, ensure the area beneath the load is clear of any obstructions and personnel. Slowly release the hand chain in a controlled manner, allowing the load to descend steadily. Avoid letting the hand chain slip through your hands too quickly, as this can cause the load to drop abruptly, posing a risk of damage or injury. Maintaining a consistent pace ensures the load is lowered safely and securely to its final position. Regularly checking the load’s balance during lowering can prevent any swinging or tilting.

Routine Maintenance Tips for Longevity

Routine maintenance is key to ensuring the long-term functionality of your manual hoist. Regular attention to the hoist’s condition can prevent major issues and extend its lifespan significantly.

Regular Cleaning Procedures

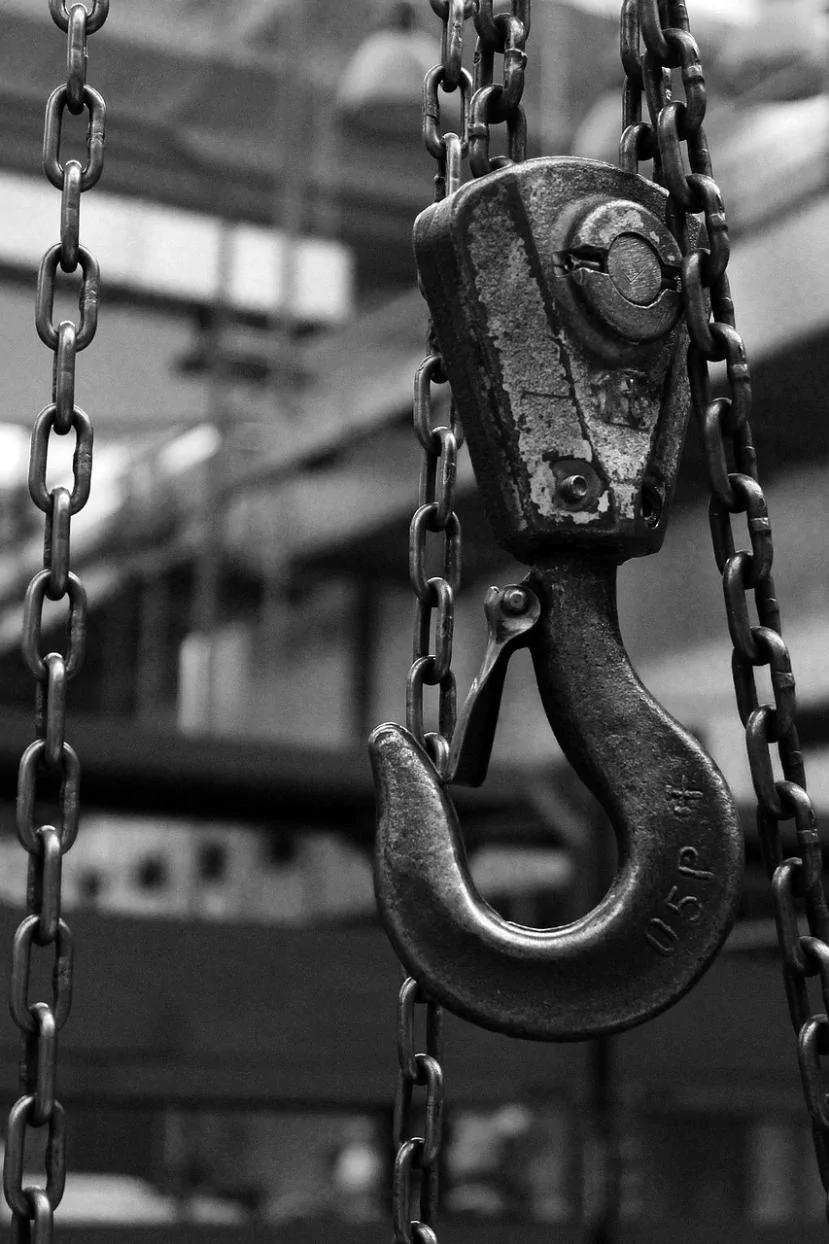

Keeping your manual hoist clean is crucial for its efficient operation. Regularly remove dirt, debris, and any substances that might accumulate on the load chain, hand chain, and gears. Use a soft brush or cloth for cleaning, avoiding high-pressure washing that might force contaminants into the hoist’s internal mechanisms. Maintaining cleanliness not only enhances the performance of your hoist but also helps in identifying wear and tear early.

Periodic Lubrication Guidelines

Lubrication reduces friction and wear on moving parts, thus prolonging the life of the hoist. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants. Ensure that all gears, rollers, and chain links are adequately lubricated. Avoid over-lubricating, as this can attract dirt and lead to gumming up the mechanisms. Proper lubrication is essential for smooth and efficient operation, making it a key part of routine maintenance.

Parts Replacement Schedule

Over time, some parts of the hoist may wear out and require replacement. Establish a parts replacement schedule based on the manufacturer’s guidelines and the hoist’s usage. Common parts that may need replacing include the load chain, hand chain, and hoist hooks. Regularly inspecting these components and replacing them as needed is crucial for maintaining the hoist’s performance and safety. Keeping a record of replacements helps track the hoist’s condition and anticipate future maintenance needs.

Troubleshooting Common Issues with Manual Hoists

Occasionally, you may encounter issues while using a manual hoist. Knowing how to troubleshoot common problems can save time and prevent potential hazards.

Load Not Lifting Smoothly

If the load does not lift smoothly, check for any obstructions or kinks in the load chain. Ensure that the load is evenly distributed and not causing any imbalances. Inspect the hoist mechanism for any signs of wear or damage. Proper lubrication of the components may also resolve the issue, ensuring smoother operation.

Strange Noises During Operation

Unusual noises during operation can indicate a problem. Listen for grinding, squeaking, or clicking sounds that might suggest worn gears or inadequate lubrication. Investigate the source of the noise and address it promptly. In some cases, disassembling the hoist for a thorough inspection and lubrication may be needed to rectify the noise.

Difficulty in Operating the Hand Chain

If the hand chain is difficult to operate, check for any twists or binds in the chain links. Ensure that the chain is not worn out and that the tension is appropriately adjusted. Lubricate the hand chain if necessary and make sure the gears and sprockets are in good condition. Addressing these issues can restore ease of operation.

Enhancing Efficiency and Ease-of-Use

To get the most out of your manual hoist, consider ways to enhance its efficiency and ease of use. Making thoughtful adjustments and additions can significantly improve your lifting operations.

Selecting the Right Hoist for the Job

Choosing the appropriate hoist for your specific task is fundamental to efficient operations. Assess the weight and size of the load, the height of the lift, and the work environment. Select a hoist with adequate capacity and features that match your requirements. A well-matched hoist reduces the risk of overloading and ensures smoother lifting.

Using Additional Accessories

Additional accessories can enhance the functionality of a manual hoist. For example, using a beam trolley helps in moving loads horizontally along a track, while a load leveler can assist in balancing uneven loads. Rigging accessories, such as slings and shackles, can help secure loads more effectively. Integrating these accessories into your lifting setup can make operations more efficient and versatile.

Apollo Manual Hoist: Elevate Your Lifting Experience

Experience the power and versatility of the Apollo Manual Hoist, the ultimate lifting solution for all your heavy-duty needs. Engineered with precision and built to last, this exceptional hoist combines cutting-edge technology with user-friendly design, ensuring effortless and efficient lifting operations.

With a robust construction and a maximum load capacity of [insert load capacity], the Apollo Manual Hoist guarantees exceptional performance in various industries, from construction sites to warehouses. Its ergonomic handle and smooth operation allow for precise control, ensuring safe and secure lifting every time.

Featuring a compact and portable design, the Apollo Manual Hoist is your reliable companion for on-the-go lifting tasks. Its easy-to-use mechanism enables quick and hassle-free setup, saving you valuable time and effort.

Practical Applications of Manual Hoists in Different Industries

Manual hoists are versatile tools used in a wide range of industries due to their efficiency and ease of use.

In the construction industry, manual hoists are essential for lifting building materials such as steel beams, concrete blocks, and roofing materials. They provide a reliable means of moving heavy items in areas where space is limited or power sources are unavailable.

In manufacturing settings, manual hoists are used to maneuver heavy machinery parts and raw materials. They facilitate assembly and maintenance operations, allowing workers to lift heavy components safely.

In shipping and warehousing, manual hoists assist in loading and unloading cargo. They help in managing heavy pallets and containers, streamlining the movement of goods within storage facilities.

In the entertainment industry, manual hoists are often used for setting up stage equipment and scenery. They provide a dependable way to lift lighting rigs, audio equipment, and stage props, ensuring that events run smoothly.

By understanding the different components, safety precautions, operational steps, maintenance practices, troubleshooting tips, and applications of manual hoists, you can maximize their efficiency and longevity, ensuring safe and reliable lifting operations in various scenarios.

Invest in the Apollo Manual Hoist today and experience the unparalleled strength and reliability that will revolutionize your lifting experience. Elevate your productivity and safety with this exceptional hoist, designed to exceed your expectations.