Lever hoists are simple, powerful, and versatile tools that you can use for lifting, pulling, or positioning heavy loads with precision and in a safe manner. They function on a sort of ratchet system, where you twist the handle up and down to raise or lower a load. With a good grasp of how lever hoists work and what their safety considerations are, would-be users can use them effectively and safely for lifting operations.

What Is the Lever Hoist?

Definition and Purpose of Lever Hoists

A lever hoist is a versatile manual lifting device used for handling heavy loads in the up, down, or accurate positioning of the lifted object. Chain hoists are different from lever hoists because most lever hoists use a ratcheting lever mechanism, thus, they can be both for horizontal and vertical operations. Those are used for heavy industries where there is a need to manipulate loads with precision and safety. They are a necessity in tight spaces or far away places due to their compact build and ease of transport.

Key Components of a Lever Hoist

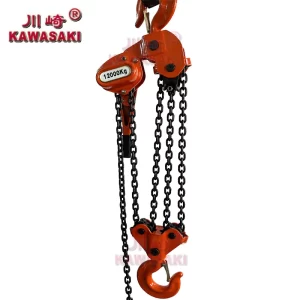

Hooks and Chains

Lever hoist hooks are usually forged alloy steel, making them durable and not easy to deform even under-loaded conditions. These hooks often have safety latches to keep the hooks from detaching accidentally while in use. Chains that are usually made of high-strength alloy steel are an important transmission component in the lifting process and making sure things are safe. They will hold plenty of force in tension and allow them to move with ease.

Lever Handle Mechanism

This mechanism is the heart of the lever hoist which is called the lever handle mechanism. It enables the manual exertion of leverage to ease the lifting and lowering of loads. The handle has an ergonomic grip, so you will get comfort even when working or using it for a long time. At its core, a ratchet system exists within the mechanism, allowing small movements and offering excellent load positioning control or complete control over load positioning.

How Does a Lever Hoist Work?

Mechanism Behind Lifting and Lowering Loads

When you pull the lever handle back and forth, you set the gears in motion to pull the chain through the housing, thus raising or lowering the attached load. This controlled motion also ensures stability and accuracy during the entire process.

The Role of Leverage in Operation

The effectiveness factor of lever hoists is leverage. These devices use mechanical advantage to help you move a heavy load with very little physical effort on your part. The longer the handle, the more leverage you have which allows you to safely and effectively move heavy loads.

Load Distribution and Safety Features

Lever hoists provide a safe mechanical advantage with features like overload protection mechanisms and braking systems that maximize stability under load pressure. In addition, they help to distribute the weight evenly among the chain links, which means less wear and tear and prolonged durability. They are also designed to distribute the weight evenly over the chain links, which decreases wear and improves durability.

What Are the Types of Lever Hoists and Their Applications?

Different Capacities for Various Industrial Needs

Lever hoists come in various capacities ranging from lightweight models for small-scale tasks to heavy-duty units capable of lifting several tons. This diversity makes them suitable for applications across multiple industries.

Common Industries Utilizing Lever Hoists

In construction, lever hoists are used for tasks like aligning steel beams or lifting building materials into place. Their compact size allows for easy transport across sites with limited access.

Manufacturing plants rely on lever hoists for assembling machinery parts or handling raw materials efficiently. In warehousing environments, they assist in stacking goods or relocating inventory safely within confined spaces.

Why Choose APOLLO Lever Hoists?

Durability and Build Quality of APOLLO Products

If we consider APOLLO, their lever hoists are specially designed from heavy-duty materials such as high-quality alloy steel chains and hooks, making them an outstanding solution. All products are subjected to stringent quality control assessments, ensuring for you the best in international standards of performance and safety including ISO9001 certification.

Advanced Safety Mechanisms in APOLLO Lever Hoists

With these designs, automatic braking systems are employed to eliminate unintentional load release and overload protection mechanisms to increase reliability in operations, forming an added safety feature also with the use of APOLLO. Such characteristics make them well-suited for high-stakes industrial applications in which precision is paramount.

Explore more about APOLLO’s lever hoists to discover how they can elevate your lifting operations with unmatched efficiency.

Ease of Operation with APOLLO’s Ergonomic Design

APOLLO products prioritize user comfort through ergonomic handles that reduce fatigue during extended use periods. Their compact design ensures portability without compromising on functionality—a perfect solution for demanding industrial environments.

Choosing the Right Lever Hoist for Your Needs

What Factors Should You Consider When Selecting a Lever Hoist?

There are some important maneuvers to consider while selecting a lever hoist, especially to guarantee its best performance and reliability. Check the lifting capacity of the hoist first. The load amount you want to lift should be less than the load limit of the hoist. The incidence of over-exploiting and accidents caused to the equipment. The next thing to consider is the material of the parts of the hoist. You need durable and heavy-duty alloy steel chains and hooks. For example, if you are working under harsh conditions with high humidity or extreme temperatures, go for the models that are specifically made for this purpose with corrosion-resistant coating and strong mechanisms.

Why Do APOLLO Products Excel in the Market?

APOLLO lever hoists are constructed for optimal strength and efficiency. Built using high-quality materials such as alloy steel chains, they are capable of long-term durability even in heavy industrial use. Also, they come with smart safety features such as an overload protection system to avoid operating accidents. Click here to learn about its brand.

Maintenance and Best Practices for Safe Operation

How Can Proper Usage Techniques Prevent Accidents?

Before the lever hoists are in use, using any tool or equipment always inspect to ensure that, everything is working. Do not use any other means and secure the load with suitable rigging and hooks and do not exceed rated loads. Do not jerk the lever handle while operating, which may lead to load instability or damage the internal mechanisms.

What Are Routine Inspection Guidelines for Lever Hoists?

Why Is Regular Checking of Hooks, Chains, and Brakes Essential?

Regular inspections can ensure your lever hoist properly functions while being safe for use. Since hooks are usually made of forged alloy steel, start by looking for any deformities in the hooks or cracks that could lead to the hook failing under load. Over time, chains can become worn, corroded or elongated, all of which may lead to a reduction in tensile strength. Likewise, test brakes to confirm that they engage under load pressure.

How Can Early Identification of Wear and Tear Save Costs?

Any strange, odd, or irregular sounds when operating or binding the movement, may indicate internal gear damage or a lack of lubricant. Regular lubrication of moving parts reduces friction and extends the life of equipment.

What Are the Benefits of Using APOLLO Lever Hoists Daily?

The APOLLO lever hoists provide numerous benefits that increase operational efficiency. The compact design of the pumps makes the pump easy to move between job sites, but they are still performance strong due to the ergonomic handles and easy-to-start design that reduce operator fatigue. Its unique precision-engineered ratchet mechanism allows wearing it smoothly and with heavy loads.

How Does APOLLO Ensure Long-Term Reliability?

APOLLO products are made to last: whole machine assembly inspection and factory performance testing assure this long-term reliability. Such processes ensure that every unit is built to high specifications of safety and reliability before it gets to customers. These processes ensure that every unit is up to the highest standards for longevity and safety before arriving in the hands of customers.

FAQs

Q1: How do I determine which lever hoist capacity is suitable?

A: Assess your maximum load requirements and choose a model with a slightly higher capacity than needed to account for unforeseen variations.

Q2: Can I use a lever hoist in outdoor environments?

A: Yes, but ensure it is designed with weather-resistant features like corrosion-resistant coatings if exposed to elements frequently.

Q3: What should I do if my lever hoist shows signs of wear?

A: Stop using it immediately and consult a professional technician for repair or replacement recommendations based on the damage extent.