Lever hoists and balancers are adaptable lifting gadgets employed across many trades. Lever hoists work via a manual lever. They deliver pinpoint command over weighty loads. This makes them apt for jobs needing exact placement. Balancers, however, keep balance using spring tension or air-driven setups. They excel in repeated tool handling. They cut down worker tiredness. Lever hoists and balancers are two distinct types of lifting equipment that serve different purposes. While both are used for lifting and moving loads, they have notable differences in their specifications and mechanisms.

What Are Lever Hoists?

Definition and Basic Mechanism

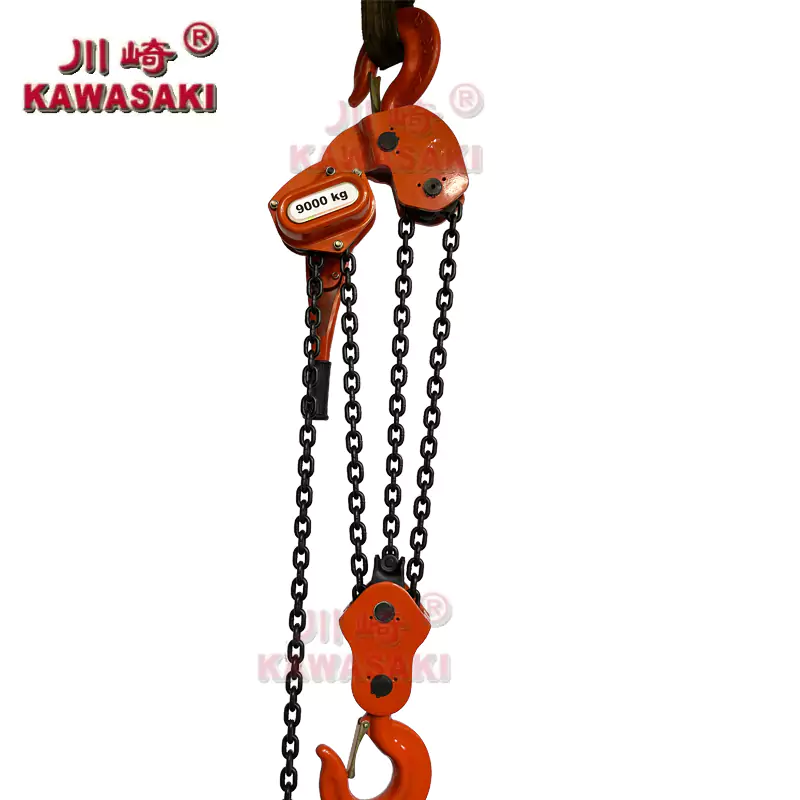

Lever hoists are flexible lifting devices used in various fields. They run by hand. They aim to raise, drop, or tug heavy weights with care. Their core system uses a ratchet and pawl setup. This allows step-by-step load movement.

Components of a Lever Hoist

A standard lever hoist has key pieces. These include the lever grip, used to run the hoist; the load chain, which carries the weight; and the hook, which links to the load. It also has a brake setup. This ensures safety during use.

Working Principle of a Lever Hoist

The lever hoist’s basic rule rests on mechanical gain. You use the lever grip to boost your effort. This lifts hefty loads easily. The ratchet system makes sure each tug moves the load a bit. It gives careful control over the task.

Applications of Lever Hoists

Lever hoists serve many industries. Their trustworthiness and ease make them popular.

Common Industries Using Lever Hoists

Sectors like building, production, and transport often use lever hoists for lifting. These tools shine where power isn’t available or practical.

Typical Tasks and Operations

Common jobs include hoisting heavy machine parts. They also tighten cables. Plus, they align gear during setup. Their hand-run nature suits far-off sites or mobile tasks.

Exploring Balancers

Definition and Basic Mechanism

Balancers are tools made to hold gear or tools at set heights. They don’t need constant hand support. They rely on a spring-powered system to offset tool weight. This allows easy use.

Applications of Balancers

Balancers thrive where tools get used over and over.

Common Industries Using Balancers

Fields like car making, tech assembly, and aerospace often use balancers. They boost worker output and ease strain.

Typical Tasks and Operations

Usual tasks include holding air tools on production lines. They also keep welding torches steady during building work. Balancers ensure stable tool spots. This improves task accuracy.

Key Functional Differences Between Lever Hoists and Balancers

Load Capacity and Weight Handling

Lever hoists are built for big weight limits with solid quality. They handle heavy loads well due to their strong make. Balancers, though, aren’t for hefty lifting. They focus on keeping tools balanced during use.

Mobility and Portability Considerations

Lever hoists’ sleek design makes them easy to carry. You can move them between work zones. They don’t need power. Balancers, however, often stay fixed at workstations. This fits their intended role.

Precision and Control in Operations

Lever hoists give exact control via their ratchet system and top-notch service. This matters when handling fragile or costly items. Balancers offer steadiness by keeping tools in place. Yet, they lack the sharp precision for big lifting jobs.

For those wanting top-grade lifting options with tweaks like OEM support, check out APOLLO’s products. They meet varied trade needs with skill and dependability.

Advantages and Disadvantages of Lever Hoists vs. Balancers

Pros and Cons of Lever Hoists

Lever hoists shine where power sources are missing. They’re built for big weight limits with steady quality. This suits them for tough lifting in building, production, and shipping fields. Their portability is a big plus. You can shift them between sites without power needs.

But there are downsides. Lever hoists need hand effort. This can tire users over long stretches. They offer sharp control via the ratchet setup. Still, they may not fit tasks needing automated or nonstop lifting.

Pros and Cons of Balancers

Balancers do well where tools get reused often, like in car making or tech assembly. They ease worker strain by holding tools at set heights. No constant hand support is needed. This boosts workplace flow. Operators can focus on fine tasks.

Their main drawback is the low weight capacity. Unlike lever hoists, balancers aren’t for heavy lifts. They aim to balance tools during use. Also, they’re usually fixed setups at workstations. This cuts their mobility compared to lever hoists.

Selecting the Right Equipment for Specific Needs

Factors to Consider When Choosing

When choosing, look at your task’s needs. Lever hoists with high output may work best for heavy lifting or spots without power. They have strong builds and easy transport. If cutting worker tiredness during tool reuse matters, balancers might suit better.

Think about the needed weight capacity. Lever hoists manage bigger loads well. Balancers give steady support for lighter tools. Check mobility too. Lever hoists are more flexible when moving than balancers, who often stay put.

Recommendations for Different Industrial Scenarios

In cases needing mobility and heavy lifting—like build sites or far-off spots—lever hoists are key. They offer fair prices and great service perks. For production lines or tasks needing steady tool spots without hand strain, balancers boost output with reliable support.

APOLLO’s Product Offerings in Lever Hoists

Overview of APOLLO’s Lever Hoist Models

APOLLO provides a wide lineup of lever hoist types. They’re made to fit many trade demands. Each model uses precise crafting for toughness and trust in harsh settings. They include features to boost safety and workflow.

Unique Features and Innovations from APOLLO

APOLLO’s lever hoists feature fresh ideas that make them stand out. Options for tweaks, including OEM support, ensure products match customer needs. Their focus on quality control means every hoist gets tough testing before shipping.

For details on APOLLO’s lever hoists and lifting tools tailored to trade uses, visit their product page.

FAQs

Q: What factors should I weigh when picking between a lever hoist and a balancer?

A: Look at the weight capacity your tasks need. Lever hoists fit heavy loads. Balancers support lighter tools steadily. Check mobility needs too. Lever hoists move more easily than fixed balancers.

Q: How do APOLLO’s lever hoist models differ in the market?

A: APOLLO offers tailored solutions with OEM support. These match specific trade needs. They back this with strong quality checks.

Q: Can balancers work in building settings?

A: Balancers suit controlled spots like production lines. Their low weight limit and fixed setup don’t fit heavy lifting common in construction.