The material handling capacity in different sectors is accelerated to a tremendous level by electric chain hoists. They are empowering because they swiftly and reliably manipulate materials and products but without requiring more physical effort or additional employees to execute these tasks.

Key Features of Electric Chain Hoists

Advanced Load Lifting Capabilities

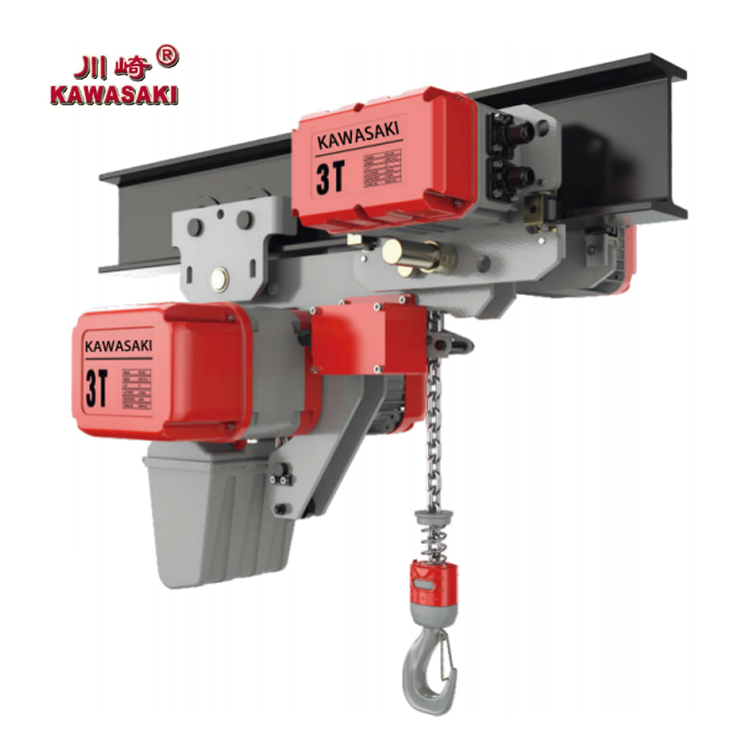

Electric chain hoists are designed to lift heavy loads with total effectiveness. They work on electric motors, which gives them an edge over manual equipment by allowing them to lift heavier materials with ease. These hoists can lift from a few hundred kilograms to several tons, making them great for a wide range of industrial applications.

Precision Control Mechanisms

Electric chain hoists place an impressive focus on accurate control systems as one of their most notable elements. They guarantee constant and precise lowering, as well as lifting of the load, thus preventing load mishaps or accidents.

More sophisticated units feature frequency converters or two-speed options so that the speed can be adapted to needs. This not only improves the efficiency of operations but also promotes the safety of handling materials.

Durability and Robust Construction

Electric chain hoists are noted for their durability. Made with superior materials like alloy steel and galvanized or nickel-plated chains, these are built to endure working conditions that can be harsh, built to last and remain effective in tough environments (such as freezing, dust, or wet conditions).

Benefits of Using Electric Chain Hoists in Material Handling

Improving Operational Efficiency

The advantages of electric chain hoists are that these equipment can automate the lifting process a great deal, thereby increasing operational efficiency. These devices work at the push of a button, as opposed to manual hoists which can take a toll on human energy not to mention the time and labor involved.

This big speed and load-carrying capacity operate without wasting time during the work process of warehouses, factories, construction sites, and other places where many are employed.

Enhancing Workplace Safety Standards

Safety is always a priority in material handling operations, and electric chain hoists offer excellent safety benefits. With features such as overload protection devices and safety limit switches, they help reduce the risk of accidents and overloading. Using their maneuverability also decreases the chances of swinging or dropping a load, which is safer for the work environment.

Reducing Manual Labor and Fatigue

Since electric chain hoists can help you lift things, they will reduce the burden on manual workers. This decrease in manual labor not only supports higher productivity but also reduces fatigue-related errors and injuries. This way, the employees are not overworked and can concentrate on other important tasks as well without sacrificing their health.

APOLLO Electric Chain Hoist Product Insights

Unique Selling Points of APOLLO Electric Chain Hoists

APOLLO electric chain hoists are high-end versatility hoists with custom features that make them incomparable. These types of products provide customized options like explosion-proof solutions for explosive environments or dust-proof for cleanroom environments.

Customizable voltage ensures global compatibility with the other power systems on the globe. Spray paint or electroplating is one surface treatment that can make it more durable without losing its entire beauty.

APOLLO undergoes extensive factory performance testing covering lifting capacity and operational stability directly tied to its unwavering commitment to quality. Before it departs from the factory, every unit passes through an extensive checklist for inspections.

Recommended APOLLO Models for Various Applications

APOLLO offers a diverse range of electric chain hoist models suited for different applications:

DCEK Series: Ideal for general industrial use with customizable options like T80/T100 chains.

KKBB Series: Designed for specialized environments requiring features such as explosion-proof or rain-proof capabilities.

Mini Wire Rope Hoist: Compact yet powerful solution for lighter loads or space-constrained areas.

European Wire Rope Hoist: Advanced models meeting stringent European standards for high-performance tasks.

Each model reflects APOLLO’s dedication to innovation and customer satisfaction through its extensive customization options.

Factors to Consider When Selecting an Electric Chain Hoist

Load Capacity Requirements

The first important factor is load capacity. When you choose an electric chain hoist. The maximum weight that your operations require the hoist to lift has to be assessed to be able to determine the capacity that the equipment needs to have to be effective and safe. Electric chain hoists are heavy-lifting machines that can lift loads from a few hundred kilograms to several tons.

Most hoists are designed to hold a certain amount of weight, but if you overload the hoist you risk its overall or safety functioning, a model that can carry at least a little more than your max requirement is recommended.

Speed and Precision Needs in Operations

Electric chain hoists are relevant to speed and precision; the more these parameters are dependent, the more utilization of the hoist is hindered in efficiency. High-speed hoists are useful in industries that need quick material handling like manufacturing and logistics.

But, if your jobs require extremely precise control—for example, assembling fragile machinery—you would want to use a model with advanced precision mechanisms. With capable features like frequency converters, many of the electric chain hoists allow users some level of customizable operating speed.

Compatibility with Existing Infrastructure

Make sure the hoist is compatible with your infrastructure before you make plans to purchase an electric chain hoist. The specifications of the hoist should match, including power supply voltage, mounting options, and workspace dimensions. Active compatibility checks help contortion in installation process and maximize operational performance.

Why Choose APOLLO Electric Chain Hoists for Material Handling?

Proven Reliability in Demanding Environments

APOLLO electric chain hoists are known for their reliability even in demanding industrial environments. Made with premium materials, including alloy steel, and have galvanized or nickel-plated chains that can endure higher extreme temperatures, dust, and moisture.

Every individual unit is factory tested to ensure the country-specific performance in terms of lifting capacity, stability and safety performance meets all international standards.

Cost-Effectiveness Over Long-Term Use

This largely translates into savings in the long run, making an APOLLO electric chain hoist a brilliant investment option! Such devices minimize the human cost associated with lifting operations, thereby increasing productivity at high speeds.

Sturdy construction reduces maintenance needs and promotes service life to carry the total ownership costs lower than manual alternatives and less robust models. APOLLO also caters to over-the-top after-sales support, along with a one-year warranty and replacement parts availability to ensure you get the most bang for your buck.

FAQs

Q1: How do I choose the correct load capacity for the electric chain hoist?

A: Consider what you will be lifting at the maximum and select a model that has a bit more capacity than what you need. This way it operates safely.

Q2: Are APOLLO electric chain hoists customizable for unique applications?

A: Yes, APOLLO offers extensive customization options including explosion-proof designs and voltage adjustments.

Q3: What maintenance is required for an electric chain hoist?

A: Regular inspections of chains, hooks, and motors are recommended to ensure optimal performance and longevity.