Using lifting clamps is essential for a variety of heavy-duty tasks, as they provide secure and efficient solutions for lifting and moving loads safely. These tools are designed with a focus on safety and effectiveness, making them highly valued across industries. They are specifically engineered to handle substantial weights while minimizing the risks associated with lifting operations.

Understanding Lifting Clamps

Definition and Purpose of Lifting Clamps

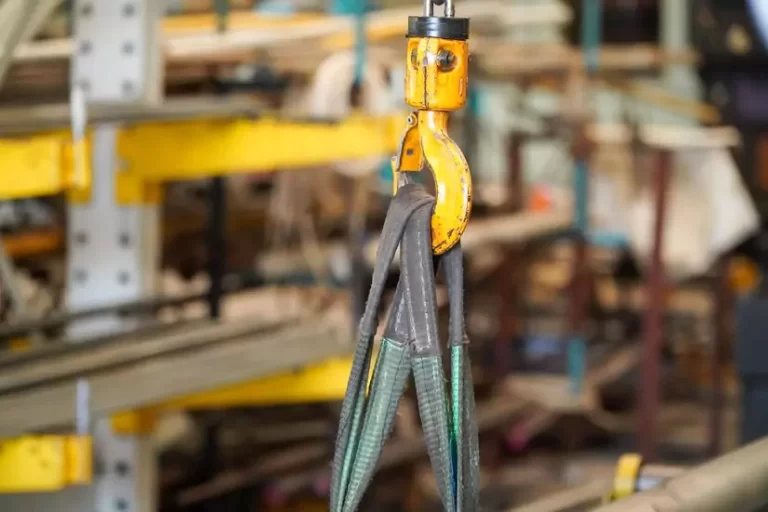

A lifting clamp is an essential tool in heavy-duty tasks and operations that involve securely and efficiently lifting and moving materials, such as metal sheets or concrete blocks, in construction or industrial settings. This tool plays a crucial role in enhancing operational efficiency while prioritizing safety measures. By securely gripping and holding the materials, a lifting clamp ensures that they can be lifted and transported without any risk of slippage or accidents. This not only improves productivity but also minimizes the potential for damage to the materials or injury to workers. Therefore, in any construction or industrial project that requires the lifting and movement of heavy materials, a lifting clamp is a valuable tool that can greatly contribute to the success and safety of the operation.

The Role of Apollo’s Lifting Clamps in the Industry

Overview of Apollo’s Product Range

Apollo is a player, in the lifting equipment industry. Provides a wide selection of lifting clamps tailored for different uses and needs. There’s a reputation for excellence and dependability associated with Apollos offerings that cater to the needs of industries, like construction manufacturing, and logistics. They offer a variety of models that are designed to handle weight capacities and meet handling needs.

Key Features of Apollo’s Lifting Clamps

Apollos lifting clamps stand out in the market due, to their range of features that enhance their performance and durability beyond others. They are made from notch steel ensuring longevity and resilience against regular wear and tear. The design is compact and lightweight for maneuverability while the reinforced hooks and surfaces offer a grip and lasting performance even in challenging situations. Not to forget Apollo’s clamps also prioritize safety with locking mechanisms, for increased security.

Benefits of Integrating Lifting Clamps into Heavy-Duty Operations

Enhancing Efficiency and Productivity

Speeding Up Load Handling

Incorporating lifting clamps into your workflow greatly boosts efficiency when handling loads efficiently and swiftly attaching and detaching them for task switching and reduced downtime leads to project completions while maintaining safety standards intact.

Reducing Manual Labor Requirements

Using lifting clamps can significantly decrease the requirement, for labor when dealing with objects. By automating lifting duties you can assign your team to specific tasks leading to a streamlined and productive process. This enhances the efficiency of your operations. Lessens the strain, on your workers.

Safety Improvements with Lifting Clamps

Minimizing Workplace Accidents

When working with loads there are some risks involved but using lifting clamps can help to lessen these dangers. The strong grip offered by clamps reduces the chances of accidents that may lead to injuries or harmful materials. Additionally, Apollo’s clamps comply with. Surpass safety standards, in the industry guaranteeing a workplace for all individuals involved.

Ensuring Compliance with Safety Standards

Ensuring safety, in heavy-duty operations is vital for both the workforce and the business itself to comply with safety regulations and avoid consequences related to safety breaches, in Apollos lifting clamps designed with strict safety measures.

Cost-Effectiveness of Using Lifting Clamps

Lowering Operational Costs

Integrating lifting clamps into your operations has the potential to result in cost savings over time. By cutting down on the time needed for loading and unloading activities you can decrease labor expenses. Optimize resource usage. Additionally, the advanced safety measures help diminish the chances of accidents and their associated costs thus adding to the effectiveness of your operations.

Extending Equipment Longevity

Using lifting clamps regularly helps protect the materials and equipment, from damage over time by providing a grip during lifts and decreasing the likelihood of wear and tear, on machinery parts due to use.

Key Applications of Apollo’s Lifting Clamps in Various Industries

Construction Industry: Building a Safer Work Environment

Steel Beam Handling

In the building sectorl any lifting equipment is crucial, for jobs such as moving metal beamsallowing them to lift steel beams with precision enhances safety and accuracyleading to the secure placement of beams without accidents This feature is vital, for the construction of safe structures

Precast Concrete Elements

Handling clamps are essential, for relocating precast components as they aid in the transportation of sizable and weighty sections for convenient on-site assembly purposes. Apollos handling clamps are adept, at managing the weight distribution of elements to ensure a reliable lifting operation on every occasion.

Manufacturing Sector: Streamlining Production Processes

Sheet Metal Fabrication

In the world of manufacturing industry workers use lifting clamps to speed up the process of making sheet metal products by handling materials to keep the workflow smooth in the workshop area where things are made easier for employees, with Apollo’s clamps help with lifting and placing sheets without causing any strain, on them resulting in better productivity overall.

Machinery Assembly

When putting together machinery pieces during assembly workmen use lifting clamps for safely lifting the components of the machines which helps speed up the assembly process and maintain production timelines on track smoothly due, to the trustworthiness of Apollos lifting clamps that allow heavy machinery to be put together without any hold-ups.

Logistic and Warehousing: Optimizing Storage Solutions

Container Load Management

Lifting clamps play a role, in managing container loads, in the logistics and warehousing industry by offering a way to lift and transport cargo efficiently while enhancing storage capabilities Apollos lifting clamps make handling containers effortless and ensure seamless operations in bustling shipping settings.

Pallet Handling

Handling pallets is another aspect where lifting clamps shine brightly as they facilitate the secure movement of pallets within warehouses which ultimately boosts effectiveness. Apollos lifting clamps are expertly crafted to streamline pallet handling processes making it easier to organize and store goods efficiently.

Selecting the Right Lifting Clamp for Your Operations

When dealing with heavy-duty tasks like lifting operations choosing the lifting clamp can greatly impact both efficiency and safety. Taking into account the specific factors that suit your requirements can enhance the effectiveness of your operations to an extent.

Key Factors to Consider When Choosing a Lifting Clamp

Load Capacity and Weight Specifications

To begin with the process of selecting lifting clamps for your tasks Start by evaluating the weight limits of each model to ensure they meet the requirements of the items you plan to lift or move safely and securely in your operations. It’s crucial to select a clamp that can handle the weight of the items you’ll be working with or even surpass those weight limits when necessary to ensure use and safety. Different tasks demand varying load capacities from lifting equipment, like plate clamps for beams or drum grabs, for lighter cylindrical objects. Understanding the weight requirements will help improve the safety and effectiveness of your lifting activities.

Material Compatibility

Choosing the lifting clamp is essential because different clamps are made for materials, like steel or aluminum components to prevent slippage or damage when lifting items up. Apollo provides a variety of lifting clamps designed for material types to give you options suited to your needs.

Recommendations from Apollo for Optimal Performance

Selecting the Appropriate Model for Specific Tasks

When you’re deciding on a lifting clamp to use for your needs and tasks, at hand. it’s helpful to pick the model that suits your requirements perfectly in Apollo’s extensive selection of products available to cater to your particular applications and needs effectively tailored for you.

Horizontal Plate Clamps

When it comes to lifting materials, like steel plates or sheets horizontal plate clamps are the way to go. They provide a hold without any risk of slipping, important when dealing with hefty loads. Apollo’s horizontal clamps are designed for positioning during lifts to ensure efficient material handling.

Vertical Plate Clamps

Vertical plate clamps have a role to play and are crucial, in their way as well. These clamps are made for lifting materials. Help maintain stability during the lifting operation. When dealing with beams or other tall objects Apollo’s vertical plate clamps offer the required hold and power to safely handle loads.

Drum Grabs

When handling cylinder-shaped objects, like drums in your operations using drum grabs is the choice. These grabs are designed to grip the drum, around its edges ensuring a safe lift. Apollos drum grabs are made to fit drum sizes allowing for handling loads with ease and flexibility.

Maintenance Best Practices for Prolonging the Lifespan of Your Lifting Clamp

It’s crucial to take care of your lifting clamps to make sure they last long and work properly. Adopting the right practices helps in keeping your equipment in shape and improves safety when using them.

Routine Inspection Guidelines

It’s important to check your lifting clamps to catch any wear and possible problems early before they get worse. Look for any signs of damage, like cracks or changes, in the clamp structure. Also, make sure the locking mechanisms work well to avoid accidents during lifting. Keeping an inspection schedule will help keep your lifting gear reliable and safe.

Importance of Proper Storage

Storing lifting clamps correctly is crucial, for their durability and longevity. It’s best to store them in an clean place after use to prevent rust and wear and tear for those crafted from alloy steel. If feasible hang the clamps on a rack. Store them in their original packaging to prevent any damage or scratches that could compromise their structural strength. Apollo prioritizes educating customers on storage practices to help prolong the lifespan of its products.

Tips on Regular Servicing Procedures

To maintain the performance and safety of your lifting clamps effectively and safely is, through servicing procedures essential for ensuring their longevity and smooth operation by lubricating moving parts to reduce friction that may cause wear over time. Additionally speaking; in cases where clamps display signs of wear and tear signs—you should seek servicing or consider replacing parts from a reliable source such as Apollo to uphold their functionality. But not least—maintaining records of all servicing conducted could be beneficial, in tracking the performance trends of the clamps over time.

Conclusion

To sum up the importance of choosing the lifting clamp for your heavy-duty tasks cannot be overstated. To boost your efficiency, in heavy lifting operations, it’s crucial to consider factors like load capacity and material compatibility. Selecting from a range of models, like plate clamps or vertical plate clamps and drum grabs can help you maximize performance. Moreover maintaining your lifting equipment following practices guarantees its reliability and effectiveness. Apollo’s wide variety of lifting clamps and knowledgeable assistance highlight their dedication to improving productivity in the heavy-duty industry. Establish them as an ally, in achieving your operational goals.