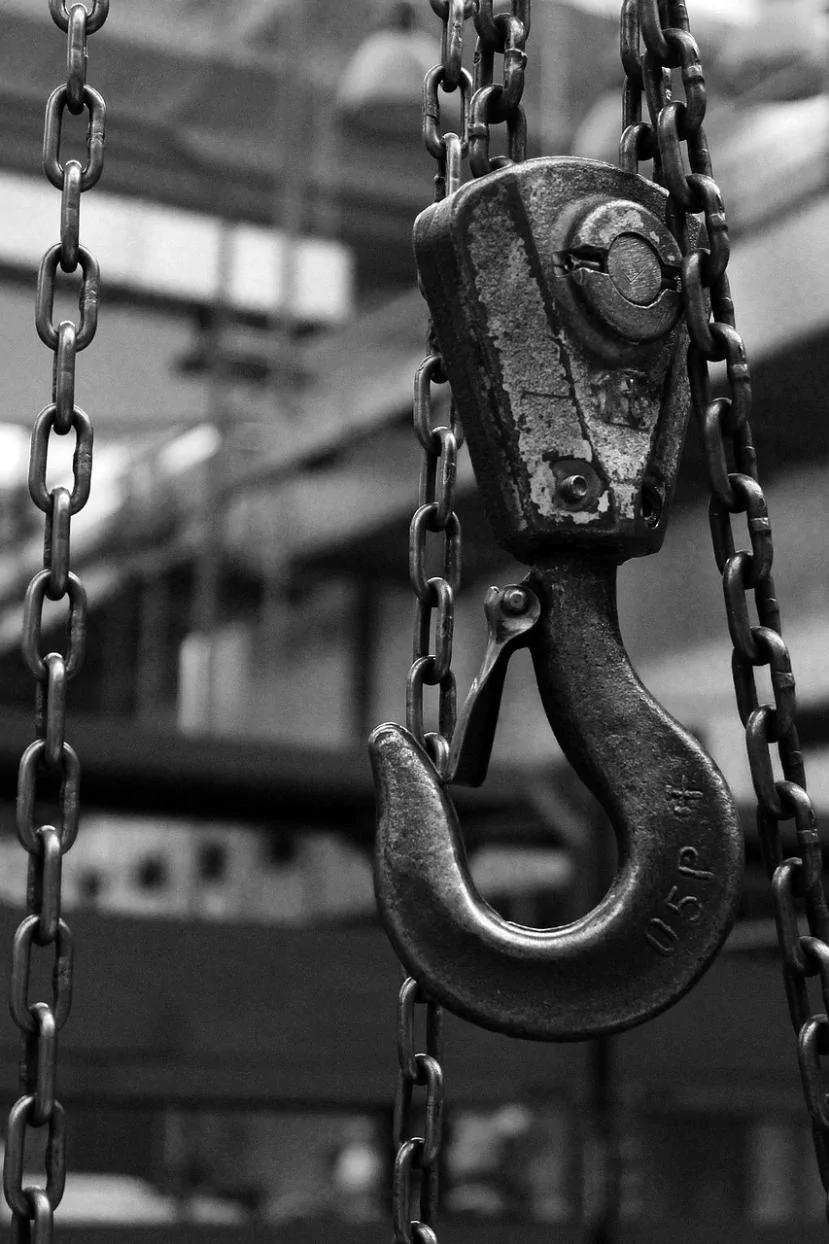

The G80 chain, a versatile and durable lifting chain, is widely used in various industrial and construction applications due to its strength, flexibility, and reliability. In this article, we’ll delve into the uses, instructions for proper handling, and the advantages of the G80 chain, providing a comprehensive understanding of its importance in the lifting industry.

Introduction to G80 Chain

G80 chain, often referred to as “grade 80 chain,” is a high-performance lifting chain made from alloy steel. The “80” refers to the minimum breaking load of the chain, which is 80 kilograms per millimeter of the chain’s cross-sectional area, or 800 MPa (Mega Pascals) of tensile strength. It is designed for use in heavy-duty lifting and rigging operations. G80 chains are typically used in hoisting, rigging, and other load-bearing applications, and they offer a balance of strength, durability, and versatility.

Understanding G80 Chain Specifications

Before discussing its usage, it’s important to understand the key specifications and properties of G80 chain:

- Tensile Strength: The chain has a minimum tensile strength of 800 MPa, making it capable of handling heavy loads.

- Material: G80 chains are manufactured from high-quality alloy steel, which provides high tensile strength while maintaining good flexibility.

- Grade Rating: G80 chains are rated as Grade 80, which means they are stronger and more durable than lower-grade chains such as Grade 70 or Grade 43 chains. The grade refers to the chain’s strength relative to its size.

- Fatigue Resistance: G80 chains are designed to withstand repeated loading cycles, providing reliability and durability over time.

- Heat Treatment: The chain undergoes a heat treatment process, which improves its overall strength and resistance to wear.

Common Uses of G80 Chain

The G80 chain is used in a variety of applications, primarily in situations where lifting or pulling is required. Here are some of the most common uses:

- Lifting and Hoisting: G80 chains are commonly used in crane operations, lifting hoists, and other lifting devices. They are often used in construction, mining, and manufacturing industries to lift heavy equipment and materials.

- Rigging and Securing Loads: G80 chains are also essential in rigging operations, where they are used to secure and move large loads. This could include securing loads on transport vehicles or attaching loads to cranes and other heavy machinery.

- Shipping and Transport: When goods are being transported, G80 chains are often used for securing cargo to prevent movement and ensure stability during transit.

- Steel Manufacturing: In steel mills, G80 chains are used to handle large metal products and materials during the production process.

- Mining and Quarrying: In mining operations, the G80 chain is used to transport and lift heavy loads such as rocks and ores.

Instructions for Proper Use of G80 Chain

To ensure the safe and efficient operation of G80 chains, it is crucial to follow correct procedures during installation, usage, and maintenance. Below are some key instructions for proper use:

1. Inspection Before Use

Before using a G80 chain, it’s essential to conduct a thorough inspection to ensure its integrity. Look for the following:

- Signs of Wear: Check for signs of excessive wear or damage, such as elongation, nicks, cracks, or deformations. Any damaged or worn-out chain should be replaced immediately.

- Corrosion: Inspect the chain for signs of corrosion, as this can compromise its strength. Corrosion can weaken the chain and cause failure under load.

- Lubrication: Ensure the chain is properly lubricated. Proper lubrication helps reduce friction and wear, extending the life of the chain.

- Certification: Ensure that the chain has been properly tested and certified for use in lifting operations. G80 chains should come with a certification that verifies their strength and durability.

2. Proper Loading

When using the G80 chain, it’s essential not to exceed the recommended working load limit (WLL). This is the maximum load the chain is designed to handle safely. Always verify the WLL for the specific chain you are using. To ensure safety:

- Avoid Overloading: Never exceed the rated capacity of the G80 chain. Overloading the chain can lead to premature failure and pose a significant safety risk.

- Use Correctly Sized Components: Ensure that the lifting hooks, shackles, and other accessories are compatible with the G80 chain in terms of size and load rating.

- Ensure Even Load Distribution: When lifting a load, ensure that the load is evenly distributed across the chain to avoid uneven stress on any one link.

3. Proper Handling

Handling G80 chain properly is crucial to its longevity and performance:

- Avoid Shock Loading: Do not allow sudden, shock-type loads on the chain, as these can cause immediate damage and reduce the chain’s lifespan. Slowly and steadily apply the load to the chain.

- Correct Positioning: Always ensure that the chain is positioned correctly, with no kinks or twists. Twisted chains can be dangerous and are more prone to failure.

- Avoid Dragging: Dragging the chain along the ground can cause unnecessary wear. Always lift the chain carefully and avoid contact with rough surfaces.

4. Storage and Maintenance

When not in use, it’s important to store G80 chains properly to prevent corrosion and damage:

- Clean the Chain: After each use, clean the chain to remove any dirt, debris, or chemicals that might cause corrosion. A clean chain will perform better and last longer.

- Dry the Chain: Ensure the chain is dry before storing it to prevent rust and corrosion from moisture.

- Proper Storage: Store the chain in a dry, clean, and well-ventilated environment. Ideally, store the chain off the ground to prevent it from coming into contact with moisture or contaminants.

- Regular Inspections: Periodically inspect the chain for signs of wear, corrosion, or damage, especially after heavy use.

Advantages of G80 Chain

The G80 chain offers a variety of advantages, making it the preferred choice for many industrial applications. These advantages include:

1. High Strength-to-Weight Ratio

One of the primary advantages of G80 chains is their high strength-to-weight ratio. The use of alloy steel and the chain’s heat treatment process allows it to support heavy loads without being excessively heavy itself. This makes it easier to handle and reduces operator fatigue, especially in lifting operations.

2. Enhanced Durability

G80 chains are highly durable and can withstand the rigors of repeated loading and unloading cycles. Their resistance to wear, fatigue, and corrosion makes them an ideal choice for heavy-duty industrial environments, where equipment is subjected to continuous use.

3. Versatility

The G80 chain is versatile and can be used in a wide range of applications, including lifting, securing, and rigging heavy loads. Whether used in construction, shipping, or manufacturing, the G80 chain is up to the task.

4. Safety

Safety is a top priority in lifting operations, and G80 chains contribute to this by providing a reliable and tested product that can handle heavy loads without breaking. When used properly and within rated capacities, G80 chains can significantly reduce the risk of accidents in lifting and rigging operations.

5. Corrosion Resistance

G80 chains are resistant to corrosion, particularly when maintained properly. This is especially important in outdoor and marine environments, where chains are exposed to elements such as rain, humidity, and saltwater. The chain’s alloy composition ensures a high level of resistance to corrosion.

6. Cost-Effectiveness

While G80 chains are generally more expensive than lower-grade chains, they provide long-term value due to their durability and strength. The cost of replacing chains that fail prematurely is often higher than investing in a higher-grade chain like G80 from the start.

7. Ease of Maintenance

The G80 chain requires relatively low maintenance compared to other types of lifting chains. Regular inspections, cleaning, and lubrication are generally sufficient to keep the chain in good working condition, further reducing operating costs.

Conclusion

The G80 chain is a powerful tool in lifting, rigging, and securing heavy loads. Its high tensile strength, durability, and versatility make it a top choice for industries ranging from construction and manufacturing to mining and shipping. However, proper handling, storage, and regular maintenance are essential to ensure the chain performs at its best and remains safe for use in critical operations. With the right care, G80 chains can provide reliable, long-lasting performance, offering significant safety and operational benefits in a wide range of applications.