When selecting a hand chain hoist manufacturer, there are several key factors to consider. It is important to choose a manufacturer that adheres to production standards and possesses relevant certifications to ensure the quality and safety of their products. Technological advancements in manufacturing, such as customization options and advanced features, are indicative of a manufacturer’s commitment to innovation. Evaluating the manufacturer’s reputation, industry experience, and customer feedback can provide insights into their reliability and expertise.

Key Characteristics of a Quality Hand Chain Hoist Manufacturer

Production Standards and Certifications

When choosing a manufacturing facility for hand chain hoists, it is crucial to consider production standards and certifications as factors in the decision-making process. A reputable manufacturer follows quality guidelines and holds important certifications to guarantee that their products meet industry standards effectively. These credentials not only confirm the safety and dependability of the machinery but also showcase the manufacturer’s dedication to delivering exceptional products. Giving preference to certified facilities when selecting a manufacturing plant for hand chain hoists ensures you can trust in the longevity and performance of the equipment.

Material Quality and Sourcing

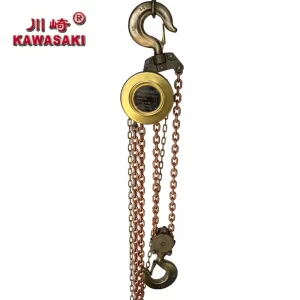

The quality of materials plays a role in the functionality of a manual chain hoist. You can depend on a manufacturer who opts for top-notch materials like specialized chains. Customizing materials is key here with choices ranging from copper alloy stainless steel to aluminum alloy, showcasing the company’s commitment to meeting diverse industrial requirements. The emphasis on using high-quality materials significantly influences how long-lasting and effective the hoists will be.

Technological Advancements in Manufacturing

Technological advancements are essential in setting leading manufacturers in the industry as they use cutting-edge technology in their production facilities to improve precision and efficiency levels significantly. Incorporating features such as 360° operation capabilities and load-limiting functions alongside scales showcases how technology enhances the functionality of products. Manufacturing plants that embrace these innovations in their operations produce hand chain hoists that are not just durable but also tailored to meet contemporary operational needs.

Evaluating the Manufacturing Process for Hand Chain Hoists

Design and Engineering Capabilities

The effectiveness of hand chain hoists is greatly affected by the design and engineering skills of the manufacturer they come from. Top-tier companies focus on creating designs that can be used in various settings like factories and farms. For example, they offer features, like explosion-proofing, dust-proofing, rain-proofing, and even frequency conversion abilities to demonstrate their technical know-how. These options give customers personalized solutions that also prioritize safety during use.

Quality Control Measures

Ensuring top-notch quality control is a must for any respected manufacturer of hand chain hoists. Plants that follow thorough inspection procedures at each production phase guarantee that flawless products are delivered to customers. From applying surface finishes, such as spray painting electroplating, or oxidation to tailoring packaging according to client choices, meticulous focus on details demonstrates a dedication to maintaining high standards of quality assurance.

Assessing the Manufacturer’s Reputation and Experience

Industry Experience and Track Record

Having a background in the industry can show how reliable and knowledgeable a manufacturer is. Plants that have been around for a while tend to have developed processes and a good understanding of what customers need. For instance, factories that can make up to 5 000 chain hoists every month prove their ability to consistently meet the needs of the market.

Customer Feedback and Testimonials

Gathering input from customers is crucial in assessing the reputation of a company that produces goods or services. Favorable comments on how products function and endure over time can offer valuable perspectives on what to anticipate from what they offer. Examining feedback from customers in sectors, such as transportation logistics or construction, can help paint a more detailed picture of the performance of their manual chain hoists in various situations.

Looking for top-notch hand chain hoists with features and expert craftsmanship? APOLLO is a standout in the industry known for its commitment to innovation and delivering tailored products that meet your requirements with top-notch material quality and engineering precision.

Understanding the Manufacturer’s Commitment to Innovation

Research and Development Initiatives

Many manufacturers show their dedication to innovation through their focus on research and development (R&D). A top-quality hand chain hoist maker puts several resources into R&D to stay current with market trends and address changing customer needs effectively. Their investments lead to the creation of cutting-edge features like explosion-proof and dust-proof qualities along with resistance to rain and advanced functions like frequency conversion and dual-speed operations that cater to a variety of uses. By giving priority to innovation in this way these manufacturers ensure that their products stay competitive and in demand within the industry.

Collaboration with Industry Experts

Working together with industry experts is a characteristic of a progressive manufacturer’s approach to innovation and growth. By collaborating with specialists in areas such as logistics, shipbuilding or construction manufacturers acquire valuable knowledge that impacts the development of their products. This partnership results in the production of hand chain hoists featuring functionalities like 360° operation load restriction capabilities and digital scales to cater to the unique requirements of various industries. These collaborations not only boost the manufacturer’s reputation but also showcase their commitment to delivering top-notch solutions.

Recommendations for Choosing a Reliable Hand Chain Hoist Manufacturer

Overview of APOLLO’s Product Offerings

When assessing manufacturers for potential partnerships or collaborations in the manufacturing industry sector or related fields of operation or interest, it is vital to take into account the range and types of products they offer to customers or clients. For example, APOLLO emerges as a reputable frontrunner in the market due to its expertise in designing and producing hand chain hoists that are specifically tailored and engineered to meet the diverse needs and demands of various industrial settings. Their product line includes a selection of options for customized chains with specific characteristics along with specialized surface treatments like spray painting, electroplating, or oxidation procedures. These unique customization features not only demonstrate their commitment to quality but also highlight their dedication to meeting and exceeding client expectations by delivering products that are precisely in line with their specified requirements. Thus solidifying their position as a reliable partner in the industry.

Apollo’s hand chain hoists are built to be versatile and cater to needs, whether in industrial settings or everyday life like farming or household chores, making them a reliable choice for all your lifting requirements with their blend of advanced functionalities and durable performance.

Advantages of Partnering with APOLLO

Opt for APOLLO as your go-to brand for hand chain hoists. Enjoy a range of benefits they offer! Their dedication to excellence shines through in their manufacturing processes and compliance with industry certifications. Furthermore, APOLLO’s ability to manufacture up to 5,000 units of chain hoists every month showcases its trustworthiness in catering to high-volume requirements while upholding top-notch quality standards.

One notable benefit is their dedication to providing customer-oriented solutions. By offering choices for customizing the brand (Original Equipment Manufacturer. OEM) as well as personalized packaging options like yellow board cartons or wooden boxes with different colors; APOLLO ensures that every feature of their product matches your preferences. This high degree of personalization doesn’t just improve effectiveness but also brings added value by efficiently meeting individual client needs.

Evaluating the Manufacturer’s Customer Service and Support

After-Sales Support Services

It’s really important to have support services after you buy a hand chain hoist from a manufacturer. The good manufacturers make sure you get all the help you need after buying like guidance for maintenance and easy access to replacement parts made for their products. When companies offer this kind of help, it shows they care about building relationships with their customers in the long run.

For example, manufacturers of custom chains such as galvanized nickel-plated or blackened varieties often provide guidelines for upkeep to extend the durability of these parts. This proactive strategy reduces interruptions and boosts user contentment by guaranteeing operations without any breaks.

Technical Assistance and Training Programs

Superior manufacturers set themselves apart from competitors through support and training initiatives. They empower operators and technical teams by offering training sessions that equip users with the necessary knowledge to optimize equipment performance securely.

These software applications frequently address subjects like operational aspects such as inverted stage hoists or specialized capabilities like riot-resistant or corrosion-resistant mechanisms. With client education, manufacturers can enhance operational efficiency and earn a reputation as dependable collaborators dedicated to boosting productivity through skill enhancement.

To choose the right-hand chain hoist manufacturer for your business needs and ensure performance across various applications, should consider these factors, innovation efforts, partnerships with industry experts, diverse product range including offerings from top brands like APOLLO, customizable options, reliable after-sales services and training programs for optimal use.