Electric hoists and electric winches are both tools that can be used for lifting or hauling, yet each one serves a very different purpose in industrial applications. They are typically employed in fields like manufacturing, construction, and warehousing, where material needs to be lifted and placed exactly.

Core Functions and Mechanisms

Primary Purpose of Electric Hoists

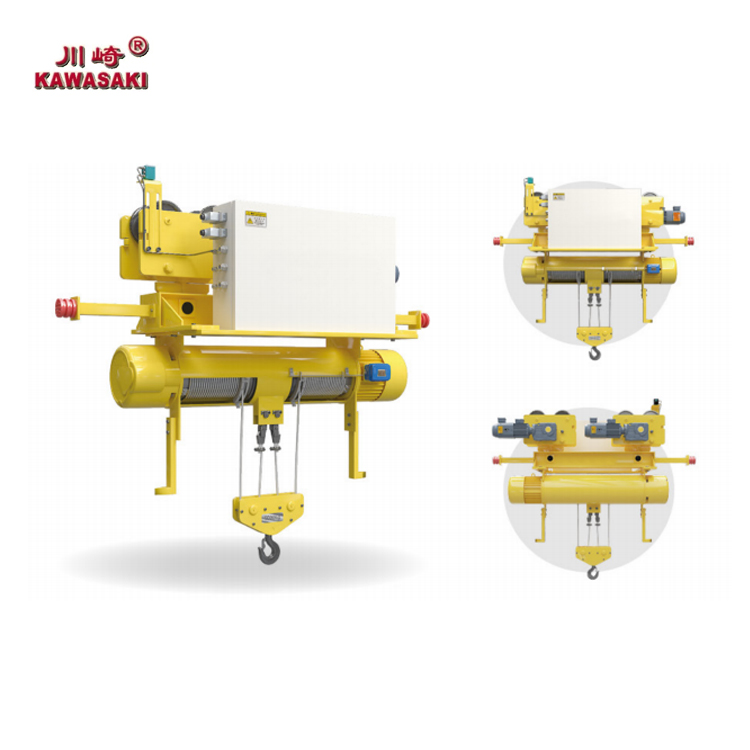

Electric hoists are used to lift and lower loads vertically and are more suited for precision lifting and lowering of heavy items. They save the need for manual lifting of items that are too heavy or large to lift otherwise.

They are propelled by electric motors that offer more substantial hoisting capabilities, further elevation levels, and more rapid function compared to manual hoists. Capable of carrying loads from a few kilograms to many tons, they are handy equipment in manufacturing, warehousing, and construction.

Specific Role of Electric Winches

Electric winches are designed for horizontal pulling or dragging. They use a motor-driven drum, on which a cable or rope is wound. It works especially well on rolling heavy objects on surfaces or in place objects being dragged.

Winches differ from electric hoists as they are not intended for vertical lifting, but they are more suitable for longer-distance applications where significant pulling force is needed.

Key Mechanical Differences

The basic mechanical difference that makes them different from electric hoists and winches is what each of their design is oriented to serve. Hoists usually integrate braking systems to stop them from dropping during a lifting procedure, while the latter focuses on torque generation for horizontal movement.

Additionally, hoists are provided with various safety devices like limit switches and overload protection devices, making the vertical lifting operation safer.

Load Handling Capabilities

Vertical Lifting with Electric Hoists

Many industries prefer vertical lifting because it reduces the footprint, and electric hoists are better suited for heavy-duty vertical lifting applications because of their strong structure and advanced features. Customized features, for example, explosion proof, frequency conversion and two-speed operation, ensure accurate load management in difficult circumstances.

Also, high lifting capacity and automation control options make it ideal for repetitive tasks for use in industrial projects.

Horizontal Pulling with Electric Winches

Electric winches are unmatched tools for any horizontal pulling application. They are capable of towing vehicles, pulling material on a construction site, or moving heavy equipment in tight places.

KAWASAKI electric winch is built to last and can also be customized for dust-proofing or rain-proofing. This is because it can work well at long ranges, making it reliable in both indoor and outdoor situations.

Weight and Load Limit Considerations

Choosing between an electric hoist and an electric winch still needs to take the camera load and weight limit of your application into account. The weight limit required to lift things will tend to be high for an electric hoist device, and so these hoists can most certainly pull more weight over their vertical distance, but it is wedded strictly to its limits, and those should always be followed to remain safe. In contrast, winches are built for pulling, but not to carry weight upward.

Applications in Industrial Settings

Common Uses of Electric Hoists in Factories and Warehouses

Electric hoists are one of the most important equipments in factories, warehouses, and industry as they help in the quick movement of goods, widely used to load and offload trucks, pile products on tall racks, or join parts on assembly lines. You might find cable or chain models, giving you a wide choice suitable for your diverse industrial needs.

Typical Scenarios for Electric Winches in Construction and Logistics

Electric winches are used in the construction sites while moving the material in the horizontal direction. They help us with things like pulling steel beams into place during the assembly of a building or moving heavy machinery across rough terrain. Winches are most commonly used in logistical operations to load cargo onto trailers or to secure objects during transport.

Safety Features and Operational Efficiency

Built-in Safety Mechanisms in Electric Hoists

With added safety features, electric hoists provide safe and efficient operation. These consist of an anti-fall brake that prevents the load from falling while lifting, overload protection devices to halt hoisting if weight far exceeds the limit, and safety limit switches to prevent the hoist from exceeding stop points. These features not only provide operational safety but also reduce the chances of accidents in the workplace.

Safety Enhancements in Modern Electric Winches

Safety features on electric winches have also evolved. Gearboxes with sealed cove protect internal moving parts from entering external contaminants like dust or water, allowing for reliable operation in harsh settings. As a side note, most modern-day winches feature a built-in braking system designed to keep the cable taut when in use and prevent any sort of rollover runaway.

Product Recommendations from APOLLO

APOLLO’s Range of Advanced Electric Hoists

APOLLO offers a comprehensive selection of electric hoists designed for diverse industrial applications. These products are engineered for durability, precision, and adaptability, meeting the highest standards of quality and performance.

Features Designed for Heavy-Duty Lifting Tasks

Electric hoists from APOLLO are designed for heavy-duty lifting purposes. They have high-powered engines to deal with heavy loads in an efficient and accurate way. Nice options ranging from custom frequency conversion controls to two-speed operational make for added precision when lifting. Customization options like frequency conversion control and two-speed work provide better control over the lifting tasks.

Industry-Specific Customization Options

APOLLO’s electric hoists can be built to serve industry-specific needs. These include explosion-proof design, dust-proof, rain-proof, and voltage compatibility. Such a degree of innovation never fails to make each product cater to a wide range of sectors be it manufacturing or warehousing.

Choosing the Right Equipment for Your Needs

Factors to Consider When Selecting Between an Electric Hoist and a Winch

Keep the below factors in mind when you need to choose between an electric hoist and a winch: Is it a vertical or horizontal load? What about the weight? What type of environment it is used in? What is the exact requirement for the application?

Due to various braking systems, overload protection, and other safety features, electric hoists are suitable for other similar vertical lifting tasks. On the other hand, electric winches work better on horizontal pulling techniques where torque is important.

How APOLLO Products Meet Diverse Industrial Requirements

Manufacturing stands at the heart of APOLLO development as the modular line of products is designed for precision-engineered solutions for diverse industrial needs focusing on safety, efficiency and customization.

Whether it is a high-end electric hoist or a need for constant load lifting with a robust and reliable winch for demanding applications, APOLLO has solutions that cater to your operational requirements. Check out what they have to offer today for equipment that enhances your productivity without compromising on safety.

FAQs

Q1: What is the difference between an electric hoist and an electric winch?

A: An electric hoist is designed for vertical lifting applications and has an integrated braking system while the electric winch is designed for horizontal pulling and used for high torque applications.

Q2: Are these devices customizable?

A: Yes! APOLLO allows a wide range of customization such as explosion-proof, surface finish (such as specialized finishes like galvanized chains), voltage compatibility adjustment (110V-575V), and others based on the requirements of the individual industrial applications.

Q3: How do I know what equipment is best for my application?

A: To determine between an electric hoist and a winch, you must evaluate factors such as load direction (vertical vs horizontal), weight capacity, environment (e.g., dust or moisture exposure), and operation objectives.