Chain hoist and chain fall feature a chain coiled around a drum or pulley setup, driven by an electric motor. When the motor starts, it pulls or releases the chain. This action enables the movement of heavy objects. Selecting the right chain hoist for your needs is critical. You must weigh factors like weight capacity, lifting range, and protective features.

The Essentials of Chain Hoists and Chain Falls

Chain hoists and chain falls serve as vital tools across numerous sectors, such as industrial manufacturing, farming, and even household tasks. These devices are commonly employed to raise and shift hefty items. Grasping the fundamentals of chain hoists and chain falls is key to ensuring safe and effective use.

Knowing the Basics of Chain Hoists and Chain Falls

Chain hoists are indispensable lifting tools used widely across industries for their ability to handle substantial loads effortlessly. They function with a chain loop, either tugged manually or powered electrically, to elevate or descend weights. APOLLO boasts decades of expertise in Taiwan. We have honed skills in crafting and ensuring the quality of lifting gear. This background guarantees that chain hoists are made with precision, delivering dependability and performance.

Chain falls, often called manual chain hoists, share similar purposes but differ in how they work. Unlike their electric counterparts, chain falls depend solely on human effort to move loads. They come with a hand chain that operators pull to hoist or lower items.

Identifying Features of Chain Hoists

Mechanical Components

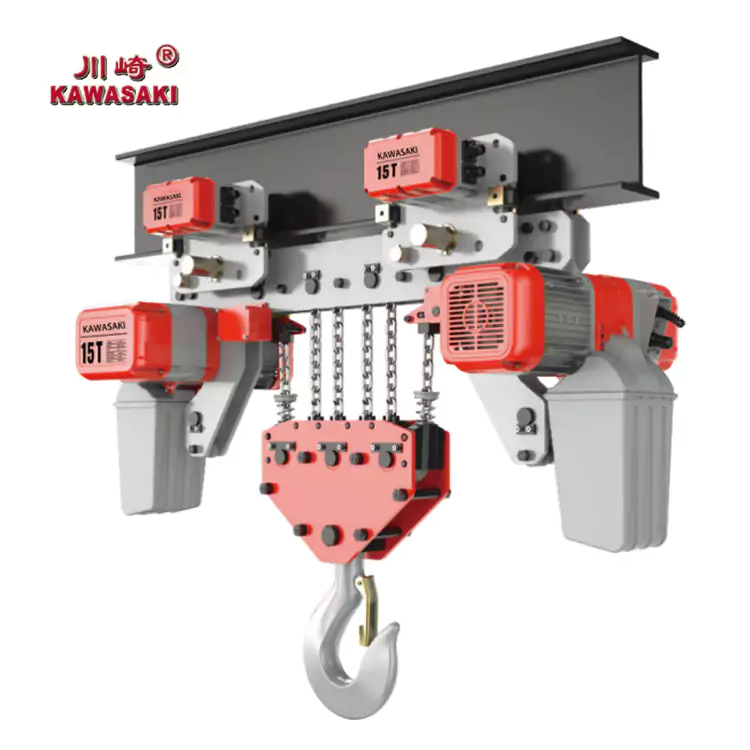

Chain hoists typically include an electric motor, gears, and a lifting hook. These parts collaborate to ensure smooth and efficient hoisting. Electric models outshine manual ones in several ways. They offer greater lifting power and improved work output. They adapt better to tough conditions. They also provide more automation and enhanced safety.

Chain hoists rely on a motorized setup. This allows quicker lifting paces and higher weight limits. In contrast, chain falls use manual effort. This can demand more labor but grants finer control over the process.

Structural Characteristics

Chain hoists are built from top-grade materials like alloy steel. This ensures strength and safety during use. The chains often consist of T8 Class high-strength links. These can support heavy loads without losing reliability.

Load Capacity Specifications

The weight capacity of chain hoists varies widely based on their build and intent. They can manage loads from a few hundred kilograms to multiple tons. This makes them ideal for demanding industrial tasks.

Usage Scenarios for Chain Hoists

Industrial Applications

Chain hoists find frequent use in places like factories, building sites, and storage facilities. Heavy lifting is routine in these areas. Their knack for managing large weights efficiently makes them essential tools.

Safety Considerations

Safety is critical when handling lifting equipment. Chain hoists include safeguards like overload protection systems. These help avoid mishaps during operation. Proper training and following safety rules are vital when using them.

Distinguishing Features of Chain Falls

Design Elements

Chain falls feature sturdy support structures designed for manual use. These setups allow precise placement of loads during lifting jobs.

Control Mechanisms

The main control for chain falls is a hand-pulled chain loop. Users tug it to raise or lower weights manually. This offers direct feedback and command over the task.

Practical Uses for Chain Falls

Common Industry Practices

Chain falls shine in situations where power sources are absent or when exact manual control is favored over automation. They suit maintenance work, small workshops, and tight spaces well.

Efficiency and Safety Factors

Chain falls may demand more physical effort than electric models. Yet, they deliver unmatched accuracy in handling loads. Their straightforward design cuts down on potential breakdowns. This boosts reliability even in tough settings.

For those seeking dependable lifting options tailored to unique needs, APOLLO provides a broad array of customizable choices via its ODM & OEM services. Whether you need specific materials or special features like explosion-proof designs or custom packaging, APOLLO offers expert support throughout the process.

Comparing Performance: Chain Hoist vs. Chain Fall

Speed and accuracy matter greatly in lifting tasks. Electric chain hoists stand out here thanks to their motorized systems. They provide swift lifting rates and precise load placement. Electric models excel over manual ones with higher weight limits and better productivity. They adapt well to harsh settings. They also offer more automation and safety. This suits them perfectly for busy industrial environments where time counts.

Meanwhile, chain falls bring a different kind of effectiveness through manual control. They may not match electric speed. However, they excel in careful load management. Operators gain direct oversight of the process. This proves useful for delicate tasks or areas without power.

Durability and Maintenance Requirements

Durability is a top concern when picking lifting gear. Chain hoists use premium materials like alloy steel. This ensures lasting use and resistance to damage. Their solid build lets them endure heavy-duty tasks without faltering.

Chain falls also show strong durability due to their basic mechanical setup. With fewer parts than electric models, they need less upkeep. They face fewer breakdowns. This simplicity extends their lifespan and cuts repair costs over time.

Choosing the Right Equipment for Your Needs with APOLLO Products

Picking the best lifting tool requires assessing your specific demands. Think about the weight of items you’ll lift and how often you’ll do it. For tough jobs with big loads or regular use, an electric chain hoist fits best. It offers superior capacity and efficiency.

On the other hand, if you deal with lighter items or lift less often, a chain fall might work better. Its manual control allows careful positioning without needing electricity.

Recommended APOLLO Products for Optimal Performance

For reliable, tailored lifting solutions, APOLLO offers a wide range of options through its ODM & OEM services. Need specific materials or unique traits like explosion-proof or dust-proof designs? APOLLO guides you expertly at every stage.

Their electric chain hoists feature advanced options like frequency control and dual-speed settings. These enhance flexibility in use. Customization includes branding and functions like rain-proofing or two-speed modes. This ensures top performance suited to your needs.

APOLLO’s manual chain hoists also shine with durability. They offer material options like stainless steel or aluminum alloy chains. You can tweak voltage or surface treatments to match your demands. This guarantees safe, reliable gear for your tasks.

FAQs:

Q1: What should I think about when deciding between a chain hoist and a chain fall?

A: Assess your lifting needs, including load weight and how often you lift. Electric hoists suit heavy tasks. Chain falls excel for lighter, precise jobs.

Q2: How do upkeep needs differ between these two tools?

A: Electric hoists may need more frequent care due to complex parts. Manual chain falls, with simpler builds, demand less maintenance.

Q3: Can I customize both types of equipment?

A: Yes, firms like APOLLO offer broad customization. This includes material choices and special features to fit your specific requirements.