Electric chain hoists and winches are both essential tools used in material handling for lifting and moving heavy loads. Electric chain hoists are designed for vertical lifting, utilizing a chain and drum mechanism powered by an electric motor. They offer precise control and are ideal for applications that require accurate vertical movement.

Understanding the Basics: Electric Chain Hoists and Winches

Definition and Functionality

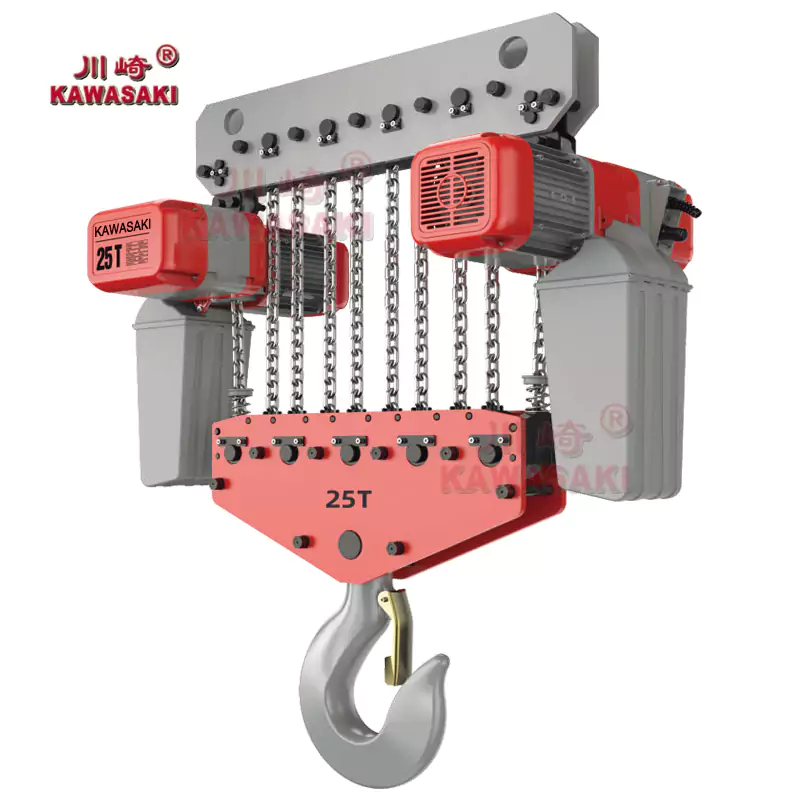

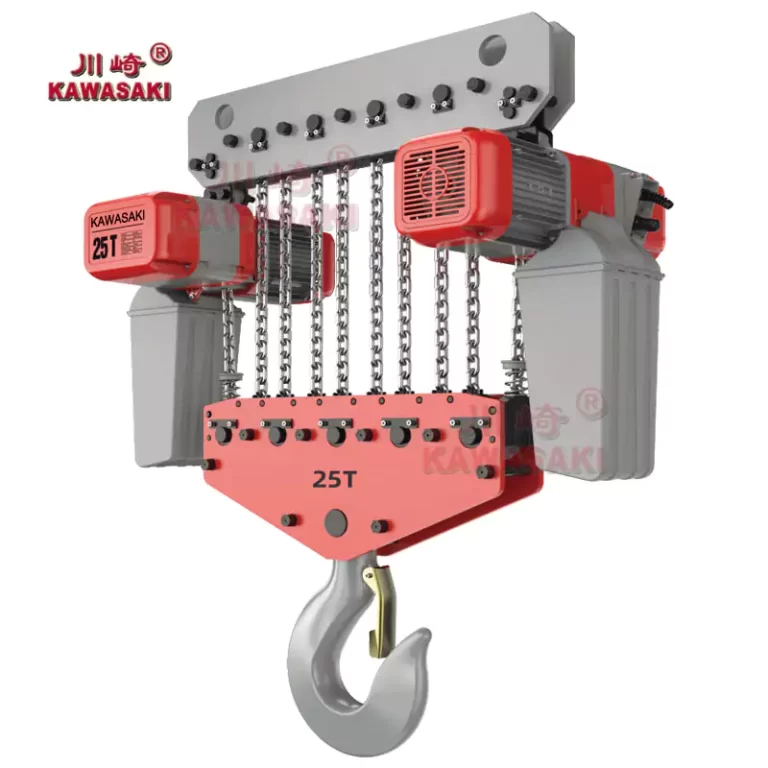

Electric chain hoists and winches are both types of equipment that serve the same basic function, which is to lift or lower heavy objects, but they are used in different applications. Electric chain hoist — A hoist used for vertical transport of loads. This system uses a chain that wraps around a drum or on a pulley system, driven by an electric motor. These features make this perfect for use cases that require accurate vertical lifting, including warehouses, manufacturing facilities, construction sites, etc.

Conversely, a winch is primarily for pulling or hauling horizontal loads over a surface. It consists of a spool (or drum) around which a cable or rope is wound. Powered manually or via an electric motor, the winch is ideal for towing vehicles or moving construction equipment across the surface of a building.

Key Differences in Design and Operation

The design and intended operation of the electric chain hoist is quite different from the electric chain hoist, and this is the fundamental difference between the two. Most electric chain hoists are designed for precision and control when lifting vertically. They usually come with features like limit switches, overload protection, and variable speed control for safe operation. Safety features such as limit switches, overload protection, and variable speed control are generally integrated for safe operations.

Cantilevered loads pull against a fixed point, and winches are capable of applying high tension through cables or ropes to do so. They are not as precise of control as hoists, but they are designed to be able to exert a very strong pulling force over a long distance. Might not possess all the precision controls that hoists do but are designed to apply tremendous pulling force over long distances

Evaluating Performance Criteria for Different Applications

Lifting vs. Pulling: Determining the Right Use Case

Before making the comparison between an electric chain hoist and a winch, it is wise to find out if your requirement is more in the context of lifting or pulling. Particularly when your job involves moving massive objects vertically and with a delicate touch, in a safe manner, they are the thing you have to use if you want an electric chain hoist. These are more efficient for tasks requiring precise control where maintaining the load is critical.

On the other hand, if your use case is more about dragging or pulling loads from one surface to another on a flat surface, a winch is a better bet. Usage hoist and winch hoist is a device that is used to lift and lower heavy or bulky objects with a direct action allowing for vertical movement.

Safety Considerations and Standards

Safety is a top priority when using both an electric chain hoist and a winch. Both of these pieces of equipment need to meet the industry standard so that they can operate safely. Electric chain hoists should meet the requirements of standards, including ANSI/ASME B30.16, which includes criteria for overhead hoists.

For winches, it might be SAE J706 for automotive winches and other appropriate standards depending on how the product is used. Abuse or failure of a part will lead to accidents, so all operators should be trained in how to use them properly to reduce the chances of mishaps.

Selecting the Right Equipment for Your Needs

Factors to Consider When Choosing Between a Hoist and a Winch

Several factors should guide your decision when selecting between an electric chain hoist and a winch:

- Load Capacity: Determine the maximum weight you need to lift or pull.

- Vertical vs Horizontal Movement: Identify whether your primary need is vertical lifting (hoist) or horizontal pulling (winch).

- Precision Requirements: Consider if precise control over movement speed and position is necessary.

- Safety Features: Evaluate available safety mechanisms like overload protection and emergency stop functions.

- Environmental Conditions: Assesswhether outdoor use requires weather-resistant features.

- Frequency of Use: Determine how often you’ll operate the equipment to choose models with appropriate durability.

Product Recommendations from APOLLO

APOLLO offers a wide range of electric chain hoists designed for reliable vertical lifting applications, featuring ATEX and IP65-rated safety features, such as automatic braking systems and thermal protection. For high-performance vertical lifting solutions with advanced safety such as automatic braking systems and thermal protection, APOLLO’s line of electric chain hoists is the right fit for your most demanding needs.

For demanding horizontal pulling tasks, APOLLO’s selection of industrial-grade winches delivers exceptional power with user-friendly controls designed for efficiency in challenging environments.

With the consideration of these factors along with reliable suggestions from industry giants such as APOLLO, professionals can choose the right equipment that meets their operational needs successfully.

Maintenance and Longevity of Equipment

Routine Maintenance Practices

A solid routine maintenance program is essential to prolonging the lifespan and ensuring the steady-state performance of electric chain hoists and winches. The chain, rope, hook, and motor should be inspected regularly for ordinary wear and tear. Parts that need to move relative to the others must be lubricated to avoid friction and premature failure. Check that all of the safety functions — limit switches and brakes — are working properly as well.

Meanwhile, special attention should be paid to chains and sprockets for electric chain hoists. This should immediately be addressed to prevent potential hazards, as signs of elongation or deformation can arise.

Extending Equipment Lifespan with Proper Care

Caring for your vehicle is not just about your daily checks; it also includes how you handle and store your equipment. In addition to proper usage, operators need to be trained in best practices about electric chain hoists and winches to ensure they are not placed under undue stress. It is critical to avoid overload, over the rated capacity is irreversible damage.

The storage conditions also contribute greatly to how long the equipment lasts. A hoist and winch should be stored in a dry place away from any corrosive elements that can damage some components. When not in use, it is recommended that you use protective measures such as covers or enclosures to protect against these environmental factors.

Conclusion: Making an Informed Decision

Aligning Equipment Choice with Operational Goals

Opting for an electric chain hoist or winch hinges upon correlating them with specific functional requirements. Whether it be lifting or pulling—is key to choosing the right equipment. Chain hoists are ideal for operations that require precision in vertical lifting (up and down), while a winch is better suited for horizontal pulling (towards you).

By choosing equipment that meets not only your performance requirements but also the safety standards relevant to your industry, you can greatly improve operational efficiencies. Considering load capacity, direction of movement, precision, safety, and environmental conditions alongside the frequency of use informs your decision so that it aligns with business goals.

Leveraging APOLLO’s Expertise in Material Handling Solutions

APOLLO helps professionals get the best handling solution that suits their needs by being the best at handling solutions. APOLLO’s range is an all-rounder collection of electric chain hoists offering high-lifting capacity and best-in-class safety features, meeting the international certificates and requirements of different industries requiring vertical movement applications with precision.

Based on their technical specifications or professional suggestions, an electric chain hoist or a winch should be used in the right place to make an informed decision. By focusing on it, one can enjoy optimized material handling operations while ensuring long-term sustainability via higher productivity and lower chances of equipment breakdown.