Explosion-proof hoists are specialized lifting equipment designed to operate safely in hazardous environments where flammable gases, vapors, dust, or other explosive substances may be present. They are used to lift and move materials or equipment in areas where traditional hoists or lifting mechanisms would pose a significant safety risk. This makes explosion-proof hoists essential for industries such as petrochemical, mining, pharmaceuticals, and any environment where volatile substances are common.

The following is a comprehensive examination of the use, importance, and key features of explosion-proof hoists.

1. Understanding Explosion-Proof Hoists

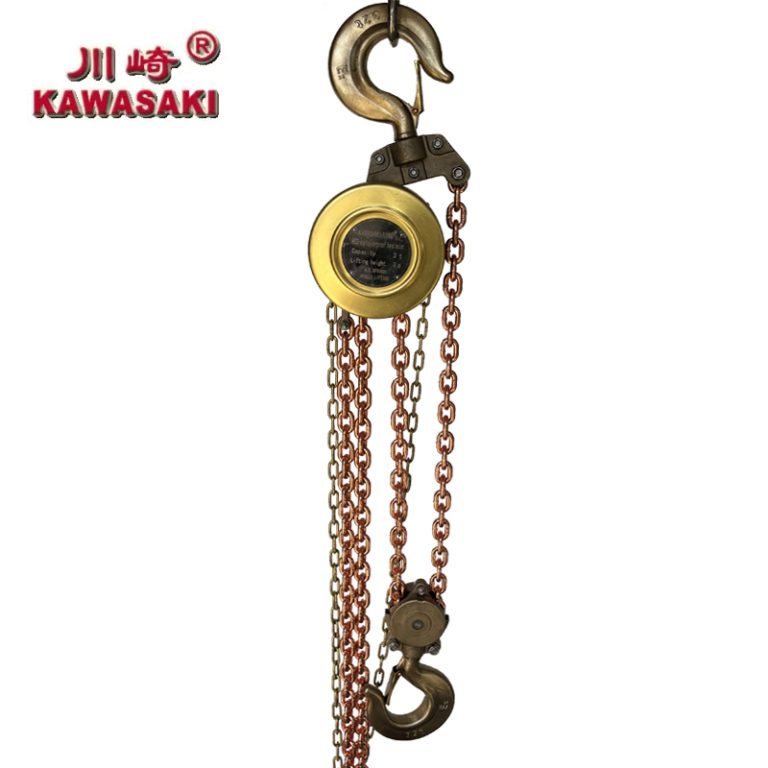

An explosion-proof hoist is a hoisting or lifting device designed to prevent the ignition of flammable materials in hazardous areas. These hoists are engineered to withstand harsh conditions and operate in areas where combustible materials could potentially ignite if exposed to sparks, heat, or electrical arcs.

There are several classifications and standards governing explosion-proof hoists. In the United States, the National Electric Code (NEC) provides guidelines, while in Europe, the ATEX directive sets the safety standards for equipment used in explosive atmospheres. These hoists are built with features that include sealed electrical components, flameproof casings, and non-sparking materials, all designed to eliminate any source of ignition.

2. Applications of Explosion-Proof Hoists

Explosion-proof hoists are critical for a wide variety of industries, particularly those where volatile substances are handled. Some of the key sectors that rely on explosion-proof hoists include:

- Chemical and Petrochemical Industries: In facilities that produce, store, or transport flammable chemicals and gases, explosion-proof hoists are necessary to prevent sparks or other ignition sources from causing catastrophic accidents. These hoists are used to lift heavy containers, chemical reactors, or piping systems.

- Mining: In underground mining operations, hoists are used to transport ore, equipment, and personnel. Mines often contain gases like methane, which can easily explode if ignited, making explosion-proof hoists essential for safety.

- Pharmaceuticals: In pharmaceutical plants, particularly those that deal with flammable powders or liquids, explosion-proof hoists are used to move raw materials and finished products safely. These materials must be handled with care to avoid contamination and explosion risks.

- Oil and Gas: The extraction, refining, and transportation of oil and gas involve highly flammable materials. Explosion-proof hoists are often used in drilling rigs, refineries, and storage facilities to move equipment and materials safely.

- Food Processing: Certain food manufacturing processes involve flammable substances or fine powders, necessitating explosion-proof equipment to maintain workplace safety.

3. Key Features of Explosion-Proof Hoists

Explosion-proof hoists differ from standard hoists in several important ways. Their design and construction include safety features that reduce the risk of ignition in hazardous environments.

- Sealed Electrical Components: Explosion-proof hoists have electrical components that are fully sealed to prevent the escape of sparks, arcs, or heat that could ignite surrounding explosive gases or dust. The seals are made from materials that can withstand extreme temperatures and pressures.

- Flameproof Casings: The external casing of an explosion-proof hoist is designed to contain any sparks, arcs, or heat that could occur during operation. This ensures that if an explosion were to occur inside the hoist, it would be contained and not transmitted to the surrounding area.

- Non-Sparking Materials: Many explosion-proof hoists use non-sparking materials such as bronze, aluminum, or stainless steel to avoid creating sparks when the hoist interacts with other materials. These materials are corrosion-resistant and durable enough to withstand the harsh conditions of hazardous environments.

- Intrinsically Safe Motors: The motor and other electrical components of the hoist are designed to prevent any electrical energy from being released in a way that could trigger an explosion. Intrinsically safe motors are a key feature of explosion-proof hoists, ensuring that they meet the required safety standards.

- Grounding and Bonding: Proper grounding and bonding are essential to prevent static buildup or electrical discharge, which could ignite an explosive atmosphere. Explosion-proof hoists are designed with these safety features built into their electrical systems.

- Explosion-Proof Certification: Explosion-proof hoists are typically certified by safety organizations such as Underwriters Laboratories (UL) or the European ATEX certification system. These certifications verify that the hoists meet strict safety standards for use in hazardous areas.

4. Standards and Regulations for Explosion-Proof Hoists

There are several important safety standards and regulations governing the use of explosion-proof hoists. These standards are designed to ensure the hoists are safe to use in hazardous environments and can be relied upon to minimize the risk of ignition.

- ATEX (Europe): The ATEX (Atmospheres Explosibles) directive is the European standard for equipment used in explosive atmospheres. It classifies hazardous areas into different zones based on the likelihood of an explosive atmosphere occurring. Hoists that meet ATEX certification are suitable for use in various hazardous environments, including those with combustible gases, vapors, and dust.

- IECEx (International): The International Electrotechnical Commission’s IECEx system provides international certification for equipment used in explosive environments. This system ensures that hoists and other equipment meet global safety standards for use in hazardous areas.

- NEC (United States): The NEC provides guidelines for equipment used in hazardous locations in the United States. It defines different classes and divisions for hazardous areas based on the type of materials present, and explosion-proof hoists must meet these requirements to ensure safe operation.

- UL Certification: Underwriters Laboratories (UL) is a globally recognized safety certification organization. UL certification ensures that explosion-proof hoists meet rigorous safety standards and are suitable for use in explosive environments.

5. Factors to Consider When Choosing an Explosion-Proof Hoist

When selecting an explosion-proof hoist for a particular application, several factors should be considered to ensure that the hoist is suitable for the specific hazardous environment.

- Hazardous Area Classification: It is crucial to understand the classification of the hazardous area where the hoist will be used. Different zones or divisions have different safety requirements, and the hoist must be chosen to meet the specific classification of the environment.

- Load Capacity: The hoist’s load capacity must be sufficient to handle the weight of the materials or equipment being lifted. This is an important factor to ensure that the hoist can perform the required tasks safely and efficiently.

- Height of Lift: The height to which the hoist needs to lift materials will impact the design and specifications of the hoist. Different hoists are designed for various lifting heights, and the appropriate hoist should be chosen for the task.

- Environmental Conditions: The environment in which the hoist will operate can affect its performance. Temperature extremes, humidity, and the presence of corrosive materials all need to be considered when selecting a hoist.

- Maintenance and Service: Explosion-proof hoists require regular maintenance to ensure they remain in safe working condition. It’s important to choose a hoist from a reputable manufacturer with a strong service and support network to ensure long-term reliability.

6. Advantages of Using Explosion-Proof Hoists

- Safety: The primary advantage of explosion-proof hoists is their ability to operate safely in hazardous environments. By preventing ignition sources such as sparks, heat, and electrical arcs, these hoists help minimize the risk of explosions, fires, and accidents in dangerous workplaces.

- Compliance with Regulations: Using explosion-proof hoists ensures that companies comply with safety standards and regulations, avoiding legal issues and costly fines. This can also help with insurance coverage and worker compensation.

- Increased Productivity: Explosion-proof hoists allow workers to safely move heavy materials and equipment in hazardous environments, increasing operational efficiency and reducing downtime caused by safety concerns.

- Durability and Longevity: Explosion-proof hoists are built to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and physical wear. This durability can result in lower maintenance costs and longer service life.

7. Challenges and Limitations of Explosion-Proof Hoists

- Cost: Explosion-proof hoists are typically more expensive than standard hoists due to their specialized design, materials, and certification. This can be a significant upfront investment for companies.

- Complexity of Installation: Installing explosion-proof hoists requires specialized knowledge to ensure they are properly set up and meet all safety standards. Incorrect installation can negate the safety benefits of the hoist.

- Maintenance Requirements: Regular maintenance is critical for the safe operation of explosion-proof hoists. Over time, the seals, casings, and electrical components may degrade, requiring more frequent inspections and repairs.

8. Conclusion

Explosion-proof hoists play a crucial role in maintaining safety in hazardous environments where combustible materials are present. Their ability to lift heavy loads without posing a risk of ignition makes them indispensable in industries such as petrochemical, mining, pharmaceuticals, and oil and gas. By adhering to strict safety standards and utilizing specialized features like flameproof casings, sealed electrical components, and non-sparking materials, these hoists help to mitigate the risk of explosions and ensure the safe operation of industrial processes. However, their higher cost, complex installation, and maintenance requirements are factors that companies need to consider when implementing them into their operations. Despite these challenges, explosion-proof hoists remain a vital component of workplace safety in hazardous areas.