Discover the fundamentals of hoists, including their functionality, types, and advantages in various industries. Learn about the differences between hoists and cranes or forklifts, and the precision and safety benefits of using a hoist. Explore Apollo’s range of lifting solutions, including the 1 Ton Electric Chain Hoist, designed to enhance efficiency and safety in your operations.

Understanding the Basics of a Hoist

Definition and Functionality of a Hoist

In fields such, as construction and manufacturing industries a hoist plays a role by lifting and lowering heavy objects using a drum or lift wheel with a rope or chain wrapped around it to move materials vertically for various tasks.

Key Components and Mechanisms

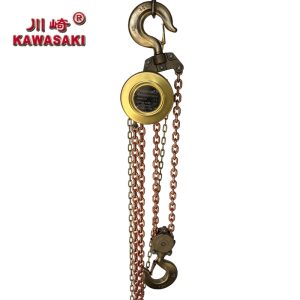

A hoist consists of parts such, as the lifting medium (chain or wire rope) a lifting hook for holding objects in place during lifting operations a motor that drives the hoist to raise and lower loads accurately, and a braking system that is crucial, for safety as it prevents unexpected drops. These components collaborate harmoniously to facilitate the handling of loads.

Types of Hoists Available

Different types of hoists cater to needs and applications. Manual hoists rely on power, while electric ones are automated using motors. Pneumatic hoists run on compressed air. They are apt for places where electricity is unsafe. Chain hoists are great, for lifting tasks while wire rope hoists ensure operation with lighter loads.

Comparing Hoists to Other Lifting Equipment

Differences Between Hoists and Cranes

Load Capacity and Range

Typically, cranes can handle loads compared to hoists. Cranes are better suited for lifting extremely heavy objects over long distances, whereas a 1-ton hoist is designed for precise lifting in tight spaces, which makes it perfect for tasks that demand accuracy over raw power.

Operational Flexibility

Compared to cranes which can operate flexibly by moving loads both vertically across areas but need ample space and infrastructure support; a 1-ton hoist stands out for its compact size and simple installation process that allows for versatility, in different environments without the need, for elaborate setup procedures.

Hoists vs. Forklifts

Mobility and Accessibility

In warehouses or industrial sitemobility isbility’s key, for transporting loads across terrains forklift trucks are a common choice due to their versatility and ease of movement. However when it comes to lifting items within spaces that forklift trucks can’t a1-ton a 1 ton hoist stands out as the preferred choice, for efficient vertical lifting operations.

Cost-Effectiveness and Efficiency

Even though forklifts can be more expensive to operate because of fuel and upkeep expenses compar1-ton a 1 ton hoist cost-effective, they, due to their energy consumption and minimal maintenance requirements efficiently boost productivity through repetitive vertical lifting tasks without hefty costs.

Advantages of Using a Hoist

Precision in Lifting Operations

When util hoist one key benefit is its handling, during lifting tasks enabling operators to place loads with accuracy and care minimizing the potential for harm or misplacement—a feature in scenarios, like assembly lines or when dealing with fragile materials.

Safety Features and Standards Compliance

Hoists come with safety measures, like overload protection and emergency stop capabilities that meet industry regulations to guarantee operations even in challenging environments and minimize the chances of incidents while handling materials.

Maintenance and Durability Considerations

Maintaining lifting equipment is essential, for its longevity and efficiency. A hoist is designed with reliable components that require minimal maintenance efforts to uphold its performance over time through regular inspections and timely servicing.

Looking for lifting solutions customized to your requirements? Consider checking out products, like the Apollo 1 Ton Electric Chain Hoist for improved efficiency and safety, in your operations.

Limitations of Hoists in Certain Applications

Load Capacity Constraints

When thinking about using a hoist it’s important to understand its limits in terms of how weight it can have A hoist is made for lifting loads within its specified range, which means it works well for tasks, in that range but does not for loads beyond that limit. In si, situations it might be better to use lifting equipment with greater load capacities, such, as cranes to ensure safety and effectiveness.

Environmental and Space Limitations

The surroundings and the space you have can make a difference in how a hoist works out for you. For example. A hoist might not be the choice, in places with high or low temperatures or environments that are corrosive unless it’s made specifically to handle those conditions. Also. If you’re working with space and tight areas that’s hard to move around in. Setting up and using a hoist can be tricky. In situations, like these. It’s crucial to pick equipment that fits both the environment and the space you’re working with.

Selecting the Right Lifting Solution for Specific Needs

Factors to Consider When Choosing a Lifting Solution

Weight and Type of Load

Choosing the lifting equipment starts with evaluating the weight and nature of the load you need to lift or move around safely and efficiently in your workspace or project site. A hoist, with a 1 ton capacity works best for loads within its specified weight limit. Is especially useful, for lifting objects that need vertical positioning control. Nevertheless‚ if you deal with types of loads or items more than 1 ton regularly ‚ you may have to consider alternative lifting solutions that can handle a wider range of weights and offer greater flexibility for your operations.

Frequency and Environment of Use

The frequency of use and environmental conditions are key considerations when selecting lifting equipment. If your operations involve frequent lifting tasks in a controlled indoor environment, a 1 ton hoist could serve you well due to its durability and minimal maintenance requirements. Conversely, if your needs include infrequent use or operation in harsh outdoor settings, alternative equipment designed for those specific conditions may be more suitable.

Recommendations for Apollo’s Products in Various Scenarios

For those seeking tailored lifting solutions that cater to diverse scenarios, exploring Apollo’s range of products can provide valuable insights. Whether you’re dealing with precision tasks requiring a 1 ton electric chain hoist or need equipment designed for specific environmental challenges, Apollo offers an array of options engineered to meet industry demands effectively.

By understanding the unique requirements of your application—such as load type, frequency of use, and environmental factors—you can make informed decisions about the most suitable lifting solution. Leveraging Apollo’s expertise ensures that you have access to reliable products that enhance operational efficiency while prioritizing safety and compliance with industry standards.