Preparing for Installation

Selecting the Right Electric Hoist for Your Garage

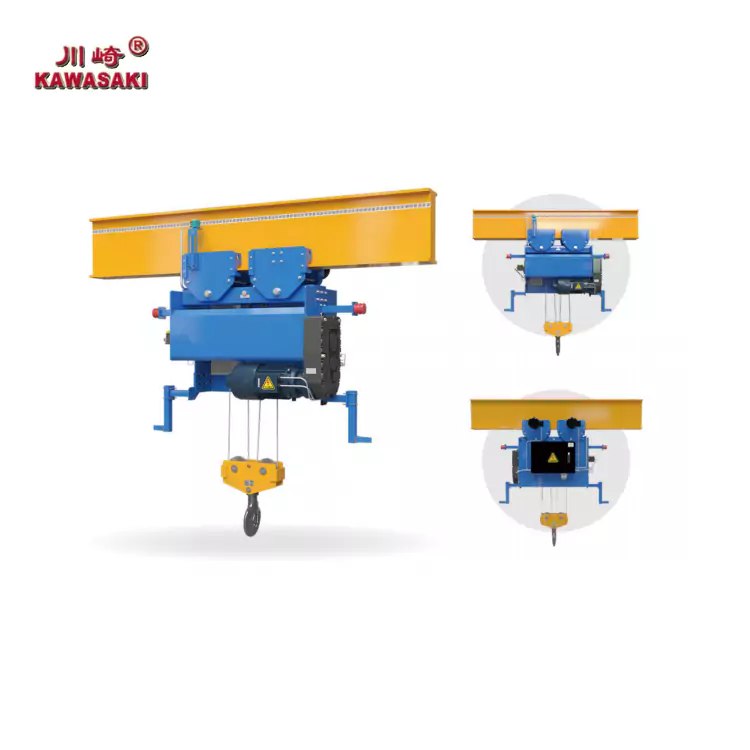

Selecting the right electric hoist for your garage is essential. Begin by determining the weight capacity necessary for your typical lifting tasks. The market provides a variety of models, including electric chain hoists and wire rope hoists, each offering different lifting capacities. Take into account any special requirements, such as features that are water-resistant, dust-proof, or explosion-proof. Choose a model that aligns with the voltage available in your home, whether it is single-phase or three-phase. Ensure to check the customization options available, like various chain materials and surface treatments, to meet your specific needs.

Gathering Necessary Tools and Materials

Before beginning the installation process, gather all necessary tools and materials. This typically includes the electric hoist unit, mounting brackets, bolts, and screws. Additional materials might include electrical wiring components and appropriate tools, such as a drill, wrenches, and screwdrivers. Have a sturdy ladder on hand for accessing high areas. It’s crucial to have everything ready before starting the project to prevent interruptions and ensure a smooth installation process.

Ensuring Safety Precautions

Safety should be your top priority when installing an electric hoist. Begin by thoroughly reading the manufacturer’s manual and safety guidelines. Wear appropriate personal protective equipment, such as gloves and safety glasses. Ensure the working area is well-lit and free from obstructions. If you’re working near any electrical components, make sure the power is switched off to prevent accidental shocks. Additionally, it’s always wise to have a second person assist you during the installation for added safety and efficiency.

APOLLO, a leading provider in the lifting equipment industry, is proud to present its exceptional range of electric hoists. With a strong focus on innovation and customer satisfaction, APOLLO offers cutting-edge solutions that meet the diverse needs of various sectors.

Our electric hoists are designed to deliver efficient, secure, and reliable performance, making them indispensable in industrial manufacturing, construction engineering, and logistics transportation. APOLLO’s electric hoists are equipped with advanced features such as anti-sway technology, automatic running capabilities, and data logging functionalities. These functions enhance operational efficiency and safety, ensuring smooth lifting operations.

One of the key advantages of APOLLO’s electric hoists is their strong customization ability. We understand that different industries have unique requirements, and our team of experts works closely with customers to design hoists that meet their specific needs. Whether it’s adapting to challenging environments or incorporating specialized features, APOLLO’s electric hoists are tailored to provide optimal performance and reliability.

Safety is a top priority at APOLLO. Our electric hoists are equipped with overload protection functions that automatically halt operations when the lifting weight exceeds the rated load. This feature prevents accidents caused by overload, ensuring the well-being of operators and the protection of valuable assets.

Additionally, APOLLO’s electric hoists incorporate intelligent control systems that enable remote operation and monitoring. This enhances operational flexibility and safety, allowing operators to control the equipment from a distance. We emphasize the importance of proper training for operators to ensure correct and safe usage of our electric hoists.

Installing the Support System

Identifying and Marking Installation Points

Start by locating suitable points in your garage where the electric hoist will be installed. These points should be able to bear the weight of the hoist and any loads it will lift. Mark these points clearly with a pencil or marker. It’s essential to measure precisely to ensure the system is installed level and stable. If unsure about the structural integrity of your ceiling or walls, consider consulting a structural engineer.

Installing Ceiling or Wall Brackets

Next, mount the ceiling or wall brackets designed to hold the electric hoist. Adhere to the manufacturer’s guidelines for proper placement of the brackets. Utilize a drill to make holes at the designated spots and fasten the brackets with suitable bolts and screws. Make certain that the brackets are level and properly aligned to support the load.

Attaching the Mounting Hardware Securely

Once the brackets are in place, the mounting hardware needs to be attached securely to the brackets. Ensure all bolts and screws are tightly fastened to avoid any movement. Double-check the strength and position of the brackets to ensure they can handle the load. This step is crucial for the overall stability and safety of the electric hoist.

Verifying the Strength and Stability of Supports

After attaching the mounting hardware, verify the strength and stability of the entire support system. Apply a gradual load to test if the supports stay firm without any signs of strain or shifts. This step ensures that the electric hoist will operate safely under full load conditions.

Electrical Setup

Understanding the Wiring Requirements

Understanding the electrical wiring requirements is essential for safely powering your electric hoist. Consult the manufacturer’s electrical guidelines and ensure compliance. Determine whether your hoist requires a single-phase or three-phase power supply. Ensure that the electrical system in your garage can handle the additional load without overloading.

Connecting the Power Supply

To connect the power supply, you need to run electrical cables from your power source to the electric hoist. It is recommended to use high-quality cables that are appropriately rated for this task. Carefully follow the wiring diagram provided in the hoist’s manual.

Choosing a Suitable Outlet or Circuit

Select a suitable outlet or circuit for the electric hoist’s power supply. Ideally, this should be a dedicated circuit to prevent electrical overloads. If necessary, install a new circuit breaker to cater to the hoist’s power demand. Make sure the circuit’s capacity matches the voltage and current requirements of the hoist.

Implementing Proper Grounding Techniques

Proper grounding is vital to ensure electrical safety. Connect the hoist’s ground wire to a reliable grounding point as specified in the manual. This connection helps prevent electrical shocks and enhances the overall safety of the electrical system. Double-check all connections to ensure they are secure and comply with safety regulations.

By following these steps, you can safely and efficiently install an electric hoist in your garage, making your lifting tasks much easier and more manageable.

Mounting the Electric Hoist

Securing the Hoist onto the Installed Brackets

With the support system securely established, the subsequent step involves attaching the electric hoist to the installed brackets. Gently lift the hoist and position it so that its mounting points align with the brackets. Make use of the provided mounting hardware, ensuring that all bolts are tightly secured. Washers should be employed where necessary to evenly distribute the load and prevent any hardware from becoming loose over time. Verify that all connections are tight before moving forward to ensure that the hoist remains stable during its operation.

Aligning and Adjusting for Optimal Performance

Once the electric hoist is secured to the brackets, aligning and adjusting it for optimal performance is essential. Make sure the hoist is correctly positioned to handle the intended load areas efficiently. Adjust the hoist’s position as needed to center it over the primary lifting area in your garage. Check the horizontal and vertical alignment by using a level to guarantee that the hoist will lift loads evenly and safely. Proper alignment not only optimizes the hoist’s efficiency but also extends its lifespan by reducing undue strain on the components.

Ensuring Correct Alignment with Load Areas

Ensuring the electric hoist is correctly aligned with load areas is pivotal for its efficient operation. Start by identifying the primary areas where the hoist will be utilized for lifting. Position the hoist so that the lifting hook or chain can easily access these areas without obstructions. This precise alignment helps in reducing the swing and translates to safer and more controlled lifts, minimizing the risk of accidents or equipment damage.

Checking Adjustment Mechanisms

After setting the alignment, check the adjustment mechanisms of the electric hoist. These mechanisms, which may include limit switches and travel control settings, are crucial for smooth operation. Verify that all adjustment controls are functioning as intended, allowing the hoist to move freely but safely within the designated parameters. Regularly test these mechanisms to ensure they respond correctly to operational commands, thereby guaranteeing the hoist’s performance remains optimal and reliable.

Testing and Final Adjustments

Conducting Initial Test Lifts

Before you start using your electric hoist regularly, it’s crucial to carry out initial test lifts to make sure everything is working properly. Begin by lifting a light load to check the hoist’s operation. Gradually increase the load while keeping an eye on the stability and performance. These test lifts help confirm that the installation is secure and that the hoist can manage the weight without any problems. If you notice any irregularities, address them before moving on to heavier loads.

Verifying Load Capacity and Stability

During the initial test lifts, it’s crucial to verify the electric hoist’s load capacity and stability. Check if the hoist lifts the load smoothly and without any jerking movements. Confirm that the system remains stable throughout the operation, with no excessive swaying or vibrations. Ensuring the hoist can handle its rated capacity without strain provides confidence in its safety and reliability for future tasks.

Observing for Any Operational Issues

Pay close attention to any operational issues that may arise during the test lifts. Listen for unusual sounds, such as grinding or squeaking, which could indicate misalignment or mechanical issues. Observe the hoist’s speed and responsiveness, ensuring that it lifts and lowers loads uniformly. Detecting and resolving these issues early helps in maintaining the hoist’s performance and prevents potential malfunctions during actual heavy lifting tasks.

Maintenance Tips for Longevity of Your Electric Hoist

Routine Inspections and Maintenance Schedule

To ensure the longevity of your electric hoist, adhere to a regular inspection and maintenance schedule. Conduct routine checks to identify any signs of wear or damage. Create a checklist to monitor essential components, such as the hoist body, chain or wire rope, hooks, and electrical wiring. Scheduled inspections help in early detection of potential issues, allowing for timely intervention. Regular maintenance extends the lifespan of the hoist and ensures consistent performance.

Lubrication and Component Care

Regular lubrication of moving components is essential for the smooth functioning of the electric hoist. Utilize the recommended lubricants for gears, chains, and other moving parts as directed by the manufacturer. Adequate lubrication minimizes friction, preventing wear and tear, and boosts the efficiency of the hoist. Moreover, consistently clean the hoist to eliminate dust and debris that could obstruct its operation. Maintaining the components in optimal condition significantly contributes to the overall durability and dependability of the hoist.

Recommended Lubricants and Techniques

Use only the recommended lubricants for your electric hoist to ensure optimal performance. Check the manufacturer’s guidelines for the types of lubricants suited to your hoist model. Apply these lubricants using appropriate techniques, such as using a brush or spray, to reach all necessary areas. Avoid over-lubrication, as excess lubricant can attract dust and cause clogging. Proper lubrication techniques maintain the smooth functioning of the hoist and prevent premature wear.

Inspecting for Wear and Tear

Regularly inspect the electric hoist for any signs of wear and tear. Focus on critical components like the load chain or wire rope, hooks, and mechanical parts. Look for visible signs of damage, such as cracks, bends, or excessive wear. Also, ensure that safety devices, such as limit switches and brakes, are functioning correctly. Timely replacement of worn-out components is crucial for maintaining the hoist’s safety and efficiency. By staying vigilant about wear and tear, you ensure the hoist operates safely and effectively over time.

Implementing these maintenance tips and conducting regular inspections will significantly contribute to the longevity and reliable performance of your electric hoist.

Maintenance and regular inspections are crucial for the longevity and optimal performance of electric hoists. APOLLO recommends routine checks for wire rope wear and tear, lubrication of transmission parts, and tightening of loose bolts. These maintenance practices ensure the equipment operates smoothly and extends its service life.

As technology continues to advance, APOLLO remains at the forefront of innovation in the lifting equipment industry. We constantly strive to improve our electric hoists by incorporating advanced motors, reduction devices, and lightweight yet durable materials. These technological advancements enhance lifting capacity, efficiency, and overall performance, further solidifying the role of APOLLO’s electric hoists across various industries.

In conclusion, APOLLO’s electric hoists are the epitome of reliability, efficiency, and safety. With our commitment to customization, advanced features, and continuous innovation, APOLLO is the ideal choice for businesses seeking top-quality electric hoists. Choose APOLLO and experience the pinnacle of lifting equipment excellence.